News

12 Year Pvd Coating Machine In Foxin

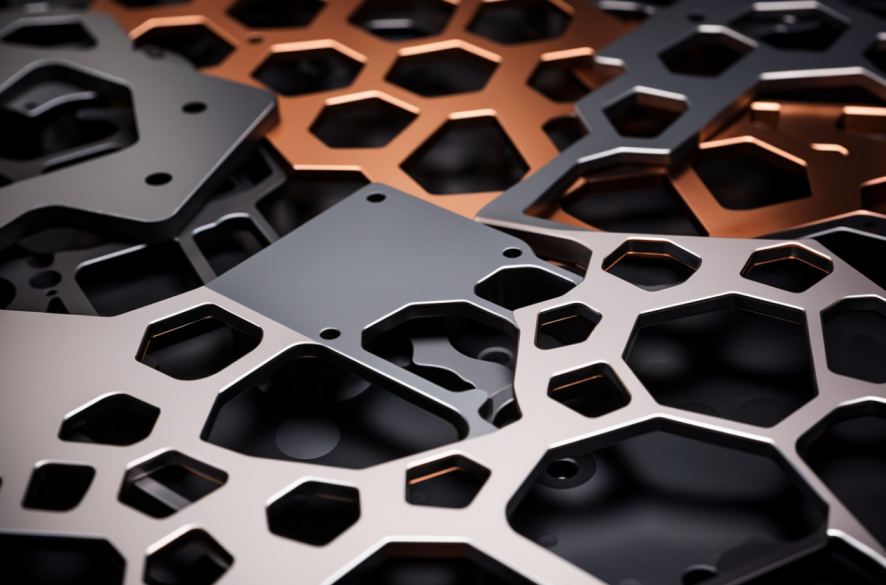

Exploring the Versatility of Aluminum PVD Coating: Enhancing Surfaces Across Industries

Unveil the potent impact of aluminum PVD coating, enriching surfaces across diverse industries. Delve into its adaptability, bolstering aesthetics, resilience, and efficiency, fueling worldwide interest. Discover the current market dynamics, emerging trends, and widespread applications, spanning watches, electronics, hardware, and precision tools. Partner with Foxin Vacuum Technology Company, renowned for crafting bespoke PVD coating solutions, and elevate your products to new heights of quality and endurance with aluminum PVD coating.

Understanding the Global Market Status

1.1 Overview of the Global Demand for PVD Coating Technologies

The global market for surface coating technologies, particularly Physical Vapor Deposition (PVD) coatings, is witnessing substantial growth. Industries worldwide are recognizing the importance of surface treatments in enhancing product performance and aesthetics, thus driving the demand for advanced coating solutions.

1.2 Growth Trends, Market Size, and Forecasts for Aluminum PVD Coating

Within the realm of PVD coatings, aluminum PVD coating stands out for its versatility and effectiveness in achieving desired surface properties. Market analysis indicates promising growth trends for aluminum PVD coating, with forecasts projecting continued expansion due to its wide-ranging applications across various sectors.

1.3 Regional Variations and Emerging Markets Driving Adoption

While the demand for aluminum PVD coating is robust globally, there are notable regional variations in adoption rates. Emerging markets in regions like Asia-Pacific, fueled by rapid industrialization and increasing consumer demand for high-quality products, are driving significant growth in the adoption of aluminum PVD coating technologies.

Applications in the Watch Industry

2.1 Importance of Aesthetics and Durability in Watch Manufacturing

In the watch industry, where aesthetics and durability are paramount, aluminum PVD coating plays a crucial role. Manufacturers strive to create timepieces that not only exude elegance but also withstand the rigors of daily wear, making aluminum PVD coating an essential solution for achieving both.

2.2 How Aluminum PVD Coating Enhances the Appearance and Longevity of Timepieces

Aluminum PVD coating enhances the appearance of watches by offering a wide range of colors, finishes, and textures. Moreover, its exceptional durability ensures that the surface maintains its pristine condition even after prolonged use, enhancing the longevity of the timepiece.

2.3 Case Studies of Leading Watch Brands Leveraging PVD Coating for Premium Finishes

Numerous leading watch brands have embraced aluminum PVD coating to differentiate their products and elevate their perceived value. By partnering with reputable manufacturers like Foxin Vacuum Technology Company, these brands have been able to achieve premium finishes that captivate consumers and set their timepieces apart.

Penetration into the 3C Industry

3.1 Role of Surface Treatment in Consumer Electronics

Surface treatment solutions play a pivotal role in the consumer electronics industry, where sleek aesthetics and durable finishes are highly sought after. Aluminum PVD coating offers a superior solution for smartphones, laptops, and other gadgets, enhancing both their appearance and durability.

3.2 Benefits of Aluminum PVD Coating for Smartphones, Laptops, and Other Gadgets

Aluminum PVD coating provides numerous benefits for consumer electronic devices, including enhanced scratch resistance, improved wear resistance, and superior corrosion protection. These properties ensure that gadgets maintain their pristine appearance and functionality over time, even with daily use.

3.3 Case Studies Showcasing Improved Scratch Resistance and Corrosion Protection

Real-world case studies demonstrate the effectiveness of aluminum PVD coating in enhancing the durability of consumer electronic devices. By applying PVD coatings to critical components, manufacturers can significantly reduce the risk of scratches, corrosion, and other forms of damage, thereby enhancing the overall lifespan of their products.

Impact on the Hardware Industry

4.1 Enhancing Functionality and Aesthetics of Hardware Products

Hardware products, such as door handles, faucets, and architectural fittings, benefit immensely from aluminum PVD coating. Not only does it enhance their visual appeal, but it also improves their functionality by providing superior protection against wear, corrosion, and environmental factors.

4.2 Applications in Door Handles, Faucets, and Architectural Fittings

Aluminum PVD coating is widely utilized in the hardware industry to create durable and aesthetically pleasing finishes for various products. Whether it’s a modern stainless steel finish or a luxurious gold tone, aluminum PVD coating can achieve the desired look while ensuring long-lasting performance.

4.3 Cost-Efficiency and Sustainability Compared to Traditional Coating Methods

One of the key advantages of aluminum PVD coating is its cost-efficiency and sustainability compared to traditional coating methods such as electroplating. PVD coating processes generate minimal waste, consume less energy, and produce superior results, making them a preferred choice for environmentally conscious manufacturers.

Precision Mold Industry Advancements

5.1 Improving Mold Lifespan and Performance with PVD Coating

In the precision mold industry, where durability and performance are paramount, aluminum PVD coating offers significant advantages. By applying PVD coatings to molds, manufacturers can improve their lifespan and performance, thereby reducing downtime and enhancing productivity.

5.2 Resistance Against Abrasion, Adhesion, and Chemical Degradation

Aluminum PVD coatings provide excellent resistance against abrasion, adhesion, and chemical degradation, ensuring that molds maintain their integrity even in demanding manufacturing environments. This resistance prolongs the lifespan of molds and reduces the need for frequent maintenance and replacements.

5.3 Customized Coating Solutions for Various Mold Materials and Designs

Foxin Vacuum Technology Company specializes in providing customized coating solutions for a wide range of mold materials and designs. By leveraging their expertise in PVD coating technology, they can tailor coatings to meet the specific requirements of their clients, ensuring optimal performance and longevity for their molds.

Empowering the Tool Industry

6.1 Importance of Tool Durability and Performance in Manufacturing

In the tool industry, where efficiency and precision are critical, aluminum PVD coating plays a vital role in enhancing tool durability and performance. By applying PVD coatings to cutting tools, drills, and inserts, manufacturers can increase their lifespan, reduce downtime, and improve overall productivity.

6.2 Role of Aluminum PVD Coating in Cutting Tools, Drills, and Inserts

Aluminum PVD coating enhances the performance of cutting tools, drills, and inserts by providing superior wear resistance and lubricity. This results in cleaner cuts, reduced friction, and extended tool life, ultimately leading to cost savings and improved machining efficiency.

6.3 Increased Tool Lifespan, Reduced Downtime, and Improved Productivity

By incorporating aluminum PVD-coated tools into their operations, manufacturers can benefit from increased tool lifespan, reduced downtime for tool changes, and improved overall productivity. This enables them to meet production demands more effectively while maintaining high standards of quality and precision.

Custom Solutions from Foxin Vacuum Technology

7.1 Overview of Foxin Vacuum Technology’s Expertise in PVD Coating Systems

Foxin Vacuum Technology Company is a leading manufacturer of PVD coating machines, known for its expertise in providing customized solutions for various industries. With a focus on innovation and quality, they have established themselves as a trusted partner for companies seeking to enhance the performance and longevity of their products through PVD coatings.

7.2 Tailored Solutions for Specific Industry Requirements

Foxin Vacuum Technology Company offers tailored solutions to meet the specific requirements of their clients across industries. Whether it’s a watch manufacturer looking to enhance the aesthetics of their timepieces or a precision mold maker seeking to improve the durability of their molds, Foxin Vacuum Technology can provide customized coating solutions to suit their needs.

7.3 Collaboration Examples Highlighting Successful Implementation and Customer Satisfaction

Through collaboration with leading companies in various sectors, Foxin Vacuum Technology Company has demonstrated its ability to deliver successful PVD coating solutions that exceed customer expectations. By understanding the unique challenges and requirements of each industry, they ensure that their clients achieve optimal results and maximum satisfaction with their coated products.

Conclusion

In conclusion, aluminum PVD coating offers a versatile and effective solution for enhancing surfaces across a wide range of industries. With its ability to improve aesthetics, durability, and performance, aluminum PVD coating is increasingly becoming the coating of choice for manufacturers worldwide. Partnering