FOXIN-GD Large Multi Arc-ion Sputtering Machine

We'll get back to you as soon as possible

FOXIN-TG Multi-Arc Ion Sputtering Coating Machine

FOXIN-GD Multi Arc Ion Coating Machine is a process of bombarding the surface of a material with an ion beam and forming a film on the surface shape. The following is the basic operation principle:

①、Material preparation: Place the large tubes or plates to be treated on the jig of the ion coating machine, ensuring that they are at a certain distance from the target surface of the coating material (coating material).

②、Discharge: By applying a high voltage to an ion source (usually a metal), an electrical discharge is generated. This causes the atoms or parts of the metal surface to ionize and form an ion beam.

③、Ion bombardment: The ion beam is released from the ion source and enters along a specific path in real space. These ion beams strike the surface of a large tube or sheet material with high energy, causing its surface to undergo biological and chemical reactions.

④、Coating shape: Ion bombardment causes atoms or fragments on the surface of the material to form a film on the surface of the tube or material. These ions form dense planar structures when deposited on the surface of the material.

⑤、Control and monitoring: Ion coaters are often equipped with control systems to monitor and regulate the energy of the ion beam, the coating rate, the coating thickness and other parameters to ensure the desired film quality and performance.

Post-processing: After the coating is complete, it may be necessary to continue with subsequent processing steps, such as cooling, cleaning, irradiation, etc., to further improve the quality and appearance of the coating.

It should be noted that the specific ion coating machine may have different construction and operation methods, so the operating principle may have all the differences. For specific equipment operation instructions, please consult FOXIN professional R & D personnel to provide documents.

Reduce Costs

We can reduce production costs because our production line is staffed with skilled technicians.

Reduce Impact

Our equipment uses a thin-film method that reduces the amount of harmful chemicals needed in the environment.

Custom Colors

Utilizing our coating equipment, you can develop fresh hues and useful coatings that will set your product apart from rivals.

Simplify

Using our equipment to coat your products in-house simplifies your supply chain process, allowing for more streamlined and efficient production.

EQUIPMENT APPLICATION

-

Stainless Steel

-

Metal

-

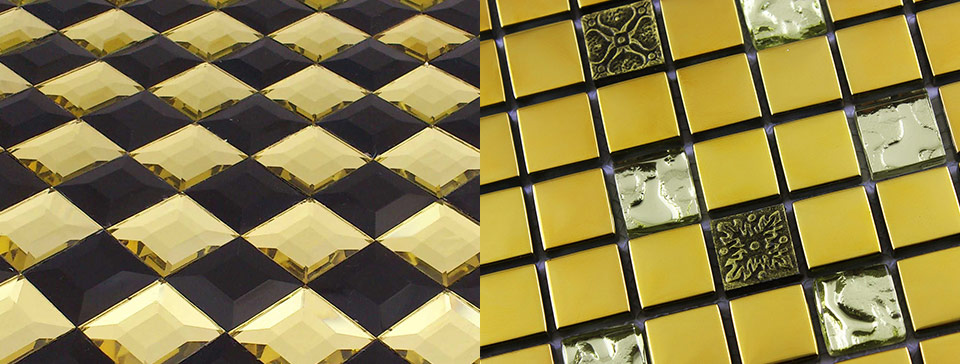

Ceramic

-

Glass

-

Plastic

{{ pro_list_app_nav_title || 'Stainless Steel' }}

-

Display Shelf

-

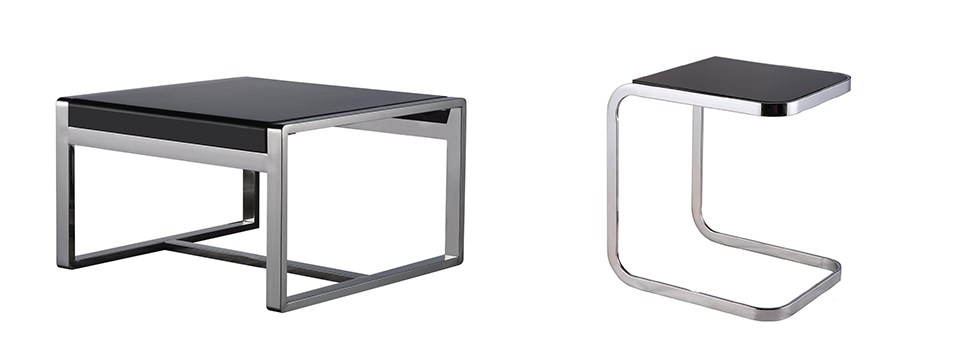

Furniture

-

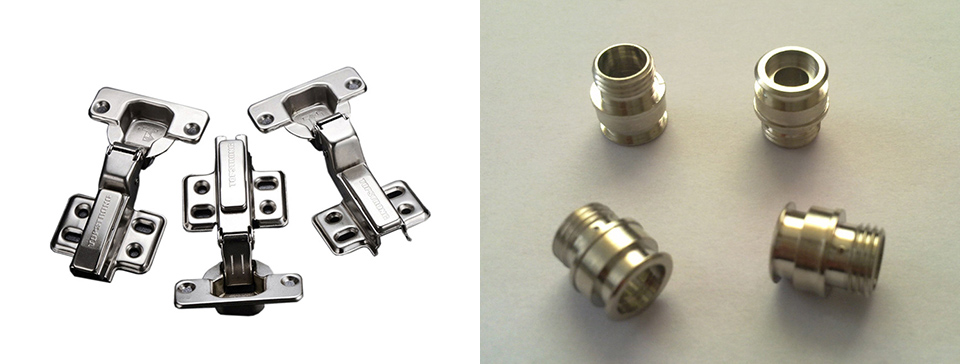

Machine part

-

Door handle

-

Ceramic-Tile floor

-

Arts And Crafts

-

The Crystal

-

Lamp Act The Role Ofing

-

Frames

-

Following From

-

Auto Parts

Would you like to know more?

To provide you with the best quality service is our commitment