Stainless Steel Sheet Gold pvd coating machine

Environmental

Customization

High quality

Delivery

-

01 Overview

-

02 Gold Pvd Coating Features:

-

03 Main Application

-

04 Download

-

05 Specifications

01 Overview

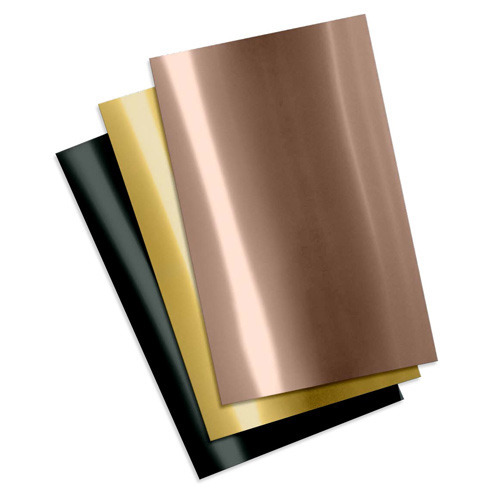

To achieve a gold color, a thin layer of gold exist onto the stainless steel sheet using a PVD process. In the same. A layer of titanium nitride (TiN) or other black material is present on the stainless steel plate. You can get black. Blue and rose gold can also get, by the PVD process. The process involves depositing a thin layer of titanium oxide . Or titanium nitride with a specific thickness. This produces the desired color.

02 Gold Pvd Coating Features:

Some of the properties of stainless steel sheet coatings in different colors include:

Durability: These coatings are very durable and resistant to scratches, fading, and wear.

Versatility: They have a wide range of applications. And can DIY. According to different stainless steel plate size and shape. This makes it suitable for various applications.

Customizability: PVD coatings can be DIY. Create a wide range of colors and finishes. Provide more choices for designers and manufacturers. This can create unique and attractive products.

03 Main Application

1、Architectural design: create unique and visually appealing designs for building exteriors and interiors.

2、Interior design: creating decorative and stylish finishes for furniture, lighting fixtures, and accessories.

3、Automotive trim: create stylish and durable finishes for automotive decorations and accessories. Appliance manufacturing: create visually appealing finishes for kitchen and home appliances.

4、Jewelry and watchmaking: create stylish and unique finishes for jewelry and watch components. Electronics:creating stylish and durable finishes for electronic devices. Such as smartphones and laptops.

04 Download

Vacuum coating overview

05 Specifications

| Model | FOXIN-GD-1840 | FOXIN-GD-2340 | FOXIN-GD-2540 | FOXIN-GD-2345 | FOXIN-GD-2548 | FOXIN-GD-2265 |

| Chamber Size(mm) | Ф1800×H4000mm2000xH3500 | Ф2300×H4000mm | Ф2500×H4000mm | Ф2300×H4500mm | Ф2500×H4800mm | Ф2200×H6500mm |

| Industry | Hardware industry, decoration industry, household appliances industry, etc | |||||

| Product | Stair handrail, household appliances, LOGO signs, stainless steel display rack, stainless steel pieces and plates, etc | |||||

| Coating Film Type | Titanium, rose gold, champagne gold, Japanese gold, silver, colorful, sapphire orchid, rose red, black and so on | |||||

| Vacuum System | Vertical door opening, hoisting or bedroom trolley structure equipped with air extraction system and water cooling system | |||||

| Vacuum Measurement | Maintenance pump + mechanical pump + Roots pump + diffusion pump or molecular pump (specific models can be configured according to customer requirements) | |||||

| Supply Type | Dc power supply, intermediate frequency power supply, pulse power supply (bias power supply, arc power supply) | |||||

| Ultimate Pressure | No-load cold state 1.0-6.0 ×10-4Pa | |||||

| Arc Source | 22set-28set | 22set-28set | 26set-32set | 26set-32set | 32set-48set | 32set-48set |

| Arc Source | 200A-300A | 200A-300A | 200A-300A | 200A-300A | 200A-300A | 200A-300A |

| Bias Power Supply | 60KW/1set | 60KW/1set | 70KW/1set | 70KW/1set | 80KW/1set | 100KW/1set |

| Rotation | Multi-axis planetary male rotation, frequency control (controllable and adjustable) | |||||

| Baking Temperature | Controllable and adjustable from normal temperature to 450℃ (PID temperature control) | |||||

| Gas | The flow control and display system of 3-channel or 4-channel process gas is equipped with automatic gas filling system | Argon, nitrogen, oxygen, acetylene, etc | ||||

| Cooling Method | Water cooling cycle, with industrial cooling tower or industrial chiller (chiller) or cryogenic system. (Provided by customer) | |||||

| Mode of control | PLC+ touch screen operation or computer control, manual, semi-automatic, automatic mode, | |||||

| Supply Index | Air pressure 0.5-0.8MPa, water temperature ≤25℃, water pressure ≥0.2MPa, | |||||

| Warning | Alarm the abnormal situation such as water shortage, overvoltage and undervoltage, circuit break, etc. of pump and target, and implement corresponding protection measures and electrical interlocking function. | |||||

| Total Power | 165~185KW | 185~200KW | 200~225KW | 225~245KW | 245~265KW | 265~300KW |

| Output Frequency | Voltage 380V±5%, frequency 50Hz (according to the customer's national electricity standard configuration) | |||||

| Occupation Space | 25~55m² | 35~55m² | 35~55m² | 45~55m² | 45~55m² | 55~75m² |

| Remark | Non-standard equipment can be designed and manufactured according to user requirements, and magnetron sputtering target and intermediate frequency twin pair target can be installed. | |||||