How Can China PVD Coater Manufacturer Adapt to Changing Market Dynamics?

Explore the forefront of PVD coating technology with Foxin Vacuum Technology Company, premier China PVD Coater Manufacturer. Renowned for innovation, Foxin drives growth in photovoltaics, integrated circuits, and magnetic materials industries. Delve into advanced deposition methods and future trends shaping the dynamic PVD coating market.

Introduction: The Crucial Role of PVD Coating Technology

In the realm of modern industrial manufacturing, the significance of Physical Vapor Deposition (PVD) coating technology cannot be overstated. This innovative process offers a versatile solution for enhancing the properties of various materials, ranging from metals to ceramics and polymers. PVD coating has extensive applications across diverse industries, including semiconductor fabrication, flat-panel display production, and solar cell manufacturing, among others. As the demand for high-performance surface treatments continues to surge globally, China has emerged as a powerhouse in PVD coating technology, catering to the evolving needs of industries worldwide.

1.1 China’s Rising Profile in PVD Coating Manufacturing

China’s ascent as a prominent manufacturer in the PVD coating industry is emblematic of its prowess in technological innovation and industrial development. Over the years, Chinese companies have made significant strides in the research, development, and production of PVD coating equipment and solutions. Their commitment to quality, efficiency, and cost-effectiveness has propelled China to the forefront of the global PVD coating market, attracting attention and acclaim from clients across diverse sectors.

1.2 Meeting the Growing Global Demand

The escalating demand for PVD coating solutions on a global scale underscores the pivotal role played by China’s manufacturers in meeting this burgeoning need. With its robust manufacturing infrastructure, skilled workforce, and strategic investments in R&D, China has positioned itself as a reliable source of high-quality PVD coating equipment and services. As industries worldwide seek to enhance the performance, durability, and aesthetics of their products, the demand for advanced surface treatment technologies like PVD coating continues to soar, creating vast opportunities for Chinese manufacturers.

Overview of China’s PVD Coater Manufacturers

2.1 Pioneers in PVD Coating Technology

China boasts a diverse array of China PVD Coater Manufacturer, each contributing to the country’s formidable presence in the global market. These companies have demonstrated remarkable growth and innovation, leveraging cutting-edge technologies to develop state-of-the-art PVD coating systems tailored to the specific needs of various industries. Among the notable players in China’s PVD coating manufacturing sector is Foxin Vacuum Technology Company, renowned for its excellence in delivering reliable, high-performance PVD coating solutions.

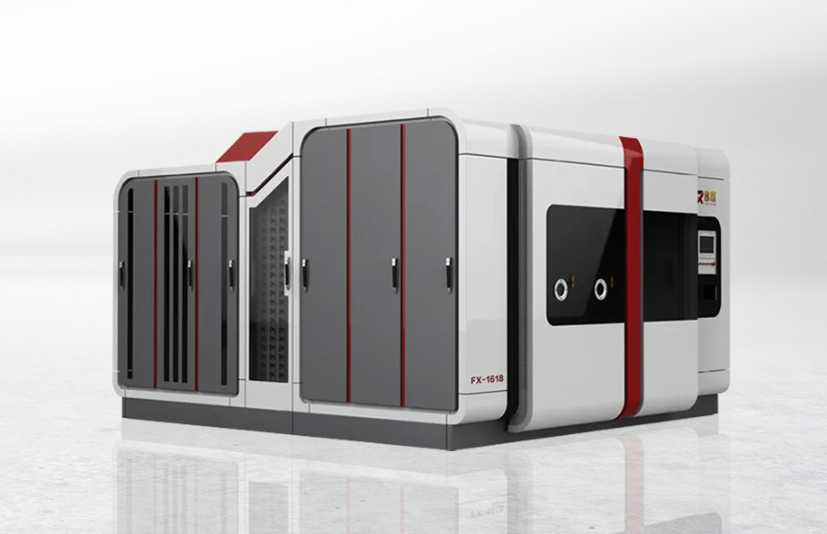

2.2 Foxin Vacuum Technology Company: A Profile

Established as a leader in the PVD coating industry, China PVD Coater Manufacturer like Foxin Vacuum Technology Company has earned acclaim for its commitment to excellence, innovation, and customer satisfaction. With a comprehensive portfolio of advanced coating systems and a team of seasoned experts, Foxin has emerged as a preferred partner for businesses seeking superior surface treatment solutions. The company’s relentless pursuit of technological advancement and its unwavering dedication to quality has cemented its reputation as a trailblazer in the field of PVD coating.

2.3 Growth Trajectory and Development Trends

The growth and development of China PVD Coater Manufacturer reflect the country’s evolution into a global hub for advanced manufacturing capabilities. With a focus on continuous improvement and expansion, these companies are poised to capitalize on emerging trends and market opportunities, driving innovation and competitiveness in the PVD coating industry. By fostering strategic partnerships, investing in talent development, and embracing sustainability practices, China’s PVD coater manufacturers are charting a path towards sustained growth and leadership in the global marketplace.

Industrial Chain Structure

4.1 Understanding the PVD Coating Materials Industry

In the intricate web of the PVD coating materials industry, the industrial chain structure encompasses both upstream and downstream components. At the upstream end, China PVD Coater Manufacturer specializes in producing high-purity metals, non-metals, compounds, and other essential materials used in the PVD coating process. Meanwhile, the downstream sector comprises end-user industries such as semiconductor manufacturing, flat-panel display production, and solar cell fabrication, which rely on PVD coating technology to enhance the performance and functionality of their products.

4.2 Collaboration and Synergy

Central to the success of the PVD coating materials industry is the seamless collaboration and synergy between upstream and downstream stakeholders. By fostering strong partnerships and communication channels, players across the industrial chain can optimize processes, streamline operations, and drive innovation. The exchange of knowledge, expertise, and resources enables the industry to adapt to evolving market dynamics, address challenges, and capitalize on emerging opportunities, thereby ensuring sustainable growth and competitiveness in the global marketplace.

Navigating the Landscape: A Market Analysis of PVD Coating Applications

5.1 Downstream Situation: A Closer Look

In the realm of PVD coating applications, the downstream situation paints a picture of diverse industries driving demand for innovative surface treatment solutions. Key sectors such as photovoltaics, integrated circuits, and magnetic materials stand out as significant contributors to the growing demand for PVD coating solutions. These industries rely on PVD technology to enhance the performance, durability, and functionality of their products, fueling the expansion of the global PVD coating market.

5.2 Photovoltaics: Harnessing Solar Power

The photovoltaic industry stands at the forefront of PVD coating applications, leveraging advanced surface treatment techniques to optimize the efficiency and longevity of solar panels. PVD-coated materials play a crucial role in enhancing light absorption, reducing reflection losses, and improving corrosion resistance, thereby increasing the overall energy conversion efficiency of solar cells. As the demand for renewable energy continues to rise, the photovoltaic sector remains a key driver of growth for the PVD coating industry.

5.3 Integrated Circuits: Empowering Electronics

Integrated circuits (ICs) represent another pivotal sector fueling the demand for PVD coating solutions. In the highly competitive electronics industry, PVD-coated materials are essential for improving the performance, reliability, and miniaturization of semiconductor devices. By applying thin films through PVD deposition methods, manufacturers can enhance the conductivity, insulation, and thermal stability of IC components, enabling the development of more advanced and efficient electronic devices.

5.4 Magnetic Materials: Driving Innovation

The utilization of PVD coating technology in the production of magnetic materials underscores its significance in driving innovation and performance optimization. PVD-coated magnets exhibit superior magnetic properties, corrosion resistance, and thermal stability, making them ideal for various applications in industries such as automotive, aerospace, and renewable energy. As demand for high-performance magnetic materials continues to grow, the PVD coating industry is poised to capitalize on this trend and expand its market presence.

Advancements in PVD Coating Technology

6.1 Evolution of Deposition Methods

Over the years, PVD coating technology has undergone significant advancements, leading to the development of more efficient and versatile deposition methods. Traditional techniques such as sputtering and evaporation have evolved to encompass a broader range of materials and substrates, enabling precise control over film thickness, composition, and properties. Additionally, the integration of innovative process monitoring and control systems has enhanced the reproducibility, uniformity, and reliability of PVD coatings, further expanding their applicability across diverse industries.

6.2 Impact on Industry Growth

The relentless pursuit of technological advancements in PVD coating technology has played a pivotal role in driving the growth and expansion of the industry. By continually pushing the boundaries of innovation, manufacturers can offer solutions that meet the evolving needs and demands of end-users, fostering greater adoption and penetration of PVD coatings across various sectors. Furthermore, advancements in deposition methods and materials have enabled the development of novel applications and products, opening up new avenues for growth and diversification within the PVD coating industry.

6.3 Future Trends and Developments

Looking ahead, the future of the PVD coating industry holds promise for continued innovation, expansion, and diversification. Emerging trends such as the integration of nanotechnology, the development of multifunctional coatings, and the adoption of environmentally friendly processes are expected to shape the trajectory of the industry in the coming years. However, alongside these opportunities, challenges such as intensifying competition, regulatory compliance, and supply chain disruptions pose potential obstacles for China’s PVD coater manufacturers.

Future Outlook and Strategies for Success

7.1 Seizing Opportunities

To stay competitive in the evolving market landscape, China’s PVD coater manufacturers must embrace innovation, collaboration, and agility. By investing in research and development, exploring new market segments, and cultivating strategic partnerships, companies can capitalize on emerging opportunities and expand their market presence. Additionally, a focus on quality, reliability, and customer satisfaction will be essential for maintaining a competitive edge in the highly competitive PVD coating industry.

7.2 Addressing Challenges

Despite the promising outlook, China PVD Coater Manufacturer must also navigate potential challenges such as rising production costs, supply chain disruptions, and intellectual property concerns. By implementing robust risk management strategies, diversifying sourcing channels, and enhancing operational efficiency, companies can mitigate these challenges and sustain long-term growth and profitability. Furthermore, proactive engagement with regulatory authorities and industry stakeholders can help address compliance issues and foster a conducive business environment for continued innovation and expansion.

Conclusion

In conclusion, China’s prominence in the PVD coating industry underscores its remarkable achievements in technological innovation, manufacturing excellence, and global competitiveness. With a vibrant ecosystem of PVD coater manufacturers, led by trailblazers like Foxin Vacuum Technology Company, China is poised to shape the future of surface treatment technology, driving growth, innovation, and sustainability across diverse industries worldwide.