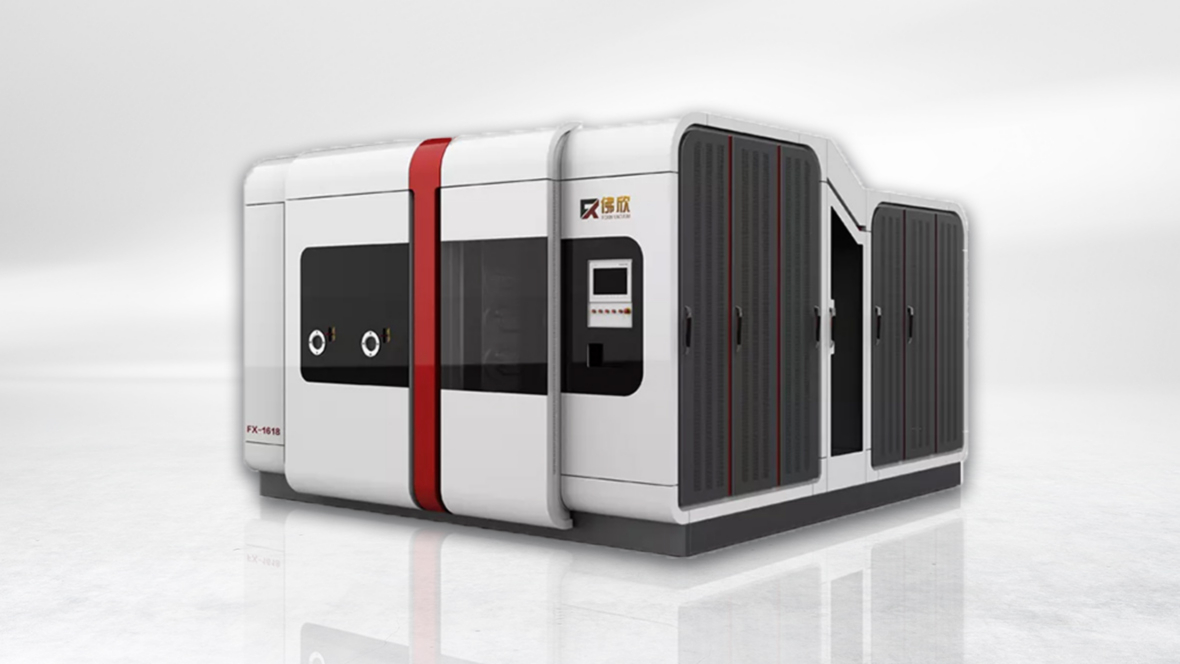

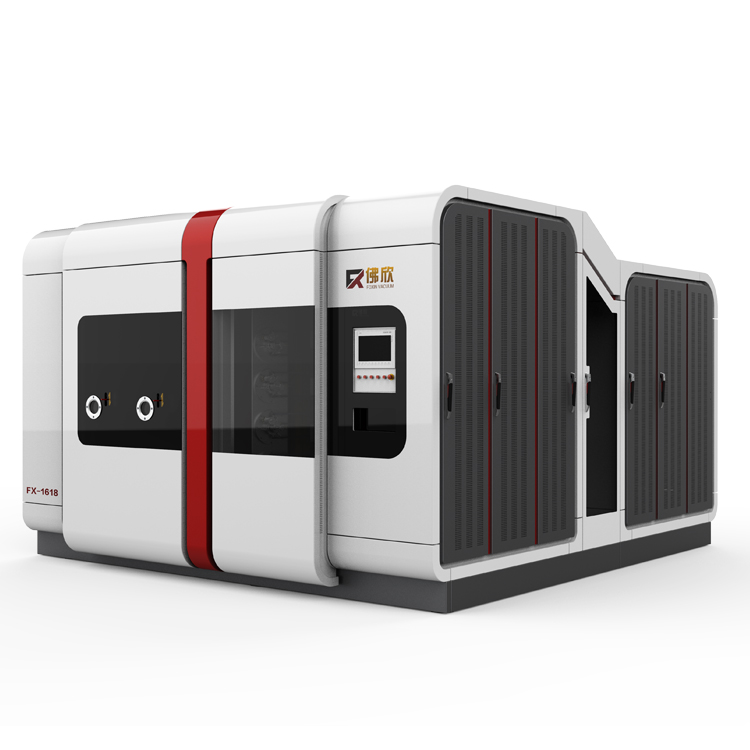

Pvd Vacuum Equipment Jewelry Plating Machine

Environmental

Customization

High quality

Delivery

-

01 Overview

-

02 The IPG Ion Plating Machine is designe with several features. To ensure the creation of high-quality coatings. Some of the notable features include:

-

03 Main Application

-

04 Download

-

05 Specifications

01 Overview

PVD jewelry plating machine.One of the primary applications of Jewelry Gold Coating Equipment is in the production of gold jewelry. It can be use to coat various types of jewelry items, including rings, necklaces, bracelets, earrings, and more.The device can generate a uniform layer of gold on the surface of jewelry. Gives it a glamorous sheen.

02 The IPG Ion Plating Machine is designe with several features. To ensure the creation of high-quality coatings. Some of the notable features include:

Multi-arc ion source: The equipment can produce different types of coatings.

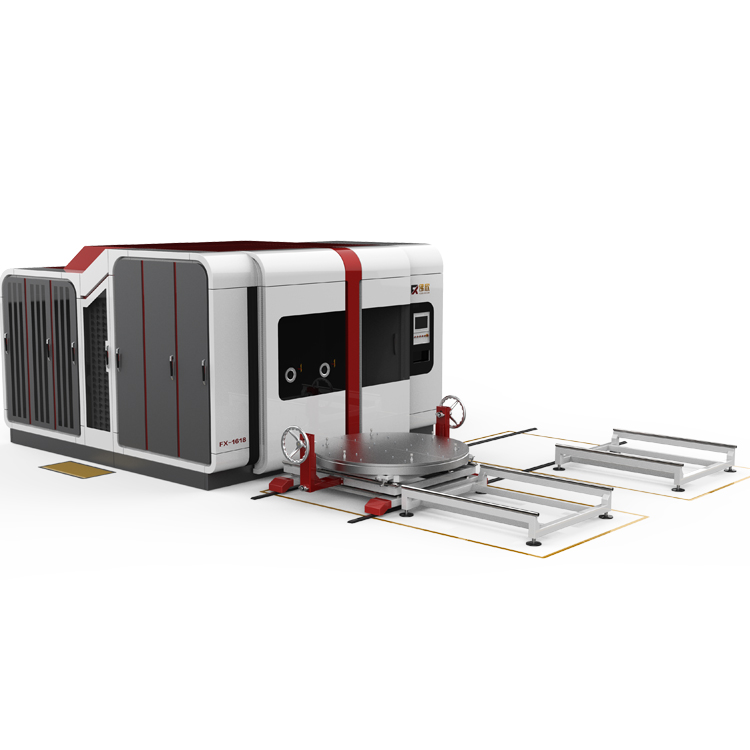

High vacuum system: The machine is equippe with a high vacuum system. A low pressure environment can be create. Ensure high quality and consistent coatings.

Substrate holder: The substrate holder securely holds the substrate. Make sure the coating is evenly deposite.

Colors: The equipment is capable of producing a range of gold colors, including yellow gold, rose gold, and black gold.

03 Main Application

1、The device is action on a variety of industries. Including aerospace, automotive, biomedical and tooling

2、Industrial Applications: It can also be use in various industrial applications. For example, it can use to coat medical implants, aerospace components and electronic components with a layer of gold. Thereby improving its durability and corrosion resistance.

3、Research and Development:It is also use for research and development. To study the characteristics and application of gold coating. It can use to develop new techniques for gold plating. As well as testing the effectiveness of different coatings on different materials

04 Download

Vacuum coating overview

05 Specifications

| Model | FOXIN-IP-0710 | FOXIN-IP-1012 | FOXIN-IP-1212 | FOXIN-IP-1412 | FOXIN-IP-1612 | FOXIN-IP-1813 |

| Chamber Size(mm) | Ф700×H1000 | Ф1000×H1200 | Ф1200×H1200 | Ф1400×H1200 | Ф1600×H1200 | Ф1800×H1300 |

| Industry | Watch industry, 3C industry, sanitary ware industry, jewelry industry, etc | |||||

| Product | Watch accessories, mobile phone accessories, glasses frames, clothing, lighting, sanitary ware, hardware bags, glass, ceramics, and plastic. | |||||

| Coating Film Type | Titanium | |||||

| Vacuum System | The vertical front door structure is equipped with air pumping system and water cooling system | |||||

| Vacuum Measurement | Maintenance pump + mechanical pump + Roots pump + diffusion pump or molecular pump (specific models can be configured according to customer requirements) | |||||

| Vacuum measuring system | One Pilani (MKS) One cold cathode (MKS) One thin film gauge (MKS) | |||||

| Supply Type | Dc power supply, intermediate frequency power supply, pulse power supply (bias power supply, arc power supply) | |||||

| Ultimate Pressure | No-load cold state 1.0-6.0 ×10-4Pa | |||||

| Arc Source | 4set-6set | 6set-8set | 8set-10set | 10set-12set | 14set-16set | 16set-18set |

| Arc Source | 200A-300A | 200A-300A | 200A-300A | 200A-300A | 200A-300A | 200A-300A |

| Bias Power Supply | 20KW | 20KW | 20KW | 30KW/1set | 40KW/1set | 60KW/1set |

| Magnetron power Supply | 1set-2set | 1set-2set | 2set-3set | 2set-3set | 3set-4set | 3set-4set |

| Rotation | Multi-axis planetary male rotation, frequency control (controllable and adjustable) | |||||

| Baking Temperature | Controllable and adjustable from -300℃ to 450℃ to 600℃ (PID temperature control) | |||||

| Gas | The flow control and display system of 3-channel or 4-channel process gas is equipped with automatic gas filling system | Argon, nitrogen, oxygen, acetylene, etc | ||||

| Cooling Method | Water cooling cycle, with industrial cooling tower or industrial chiller (chiller) or cryogenic system. (Provided by customer) | |||||

| Mode of control | PLC+ touch screen operation or computer control, manual, semi-automatic, automatic mode, | |||||

| Supply Index | Air pressure 0.5-0.8MPa, water temperature ≤25℃, water pressure ≥0.2MPa, | |||||

| Warning | Alarm the abnormal situation such as water shortage, overvoltage and undervoltage, circuit break, etc. of pump and target, and implement corresponding protection measures and electrical interlocking function. | |||||

| Total Power | 25~65KW | 45~85KW | 65~105KW | 85~115KW | 95~125KW | 100~130KW |

| Output Frequency | Voltage 380V±5%, frequency 50Hz (according to the customer's national electricity standard configuration) | |||||

| Occupation Space | 15~50m² | 15~50m² | 25~55m² | 25~55m² | 35~55m² | 35~55m² |

| Remark | Non-standard equipment can be designed and manufactured according to user requirements, and magnetron sputtering target and intermediate frequency twin pair target can be installed. | |||||