High performance Pvd vacuum coating machine for stainless steel plates and stainless steel accessories

Environmental

Customization

High quality

Delivery

-

01 Overview

-

02 Features

-

03 Main Application

-

04 Download

-

05 Specifications

01 Overview

The PVD vacuum coating machine is used to deposit thin films on various substrates. Includes stainless steel plate. The role of PVD coating on stainless steel plate is to enhance the surface properties. Such as corrosion resistance, wear resistance, aesthetics, etc.

02 Features

Multi-functional coating: High-performance PVD vacuum coating machines can apply a variety of coatings. Including titanium nitride, titanium carbonitride, chromium nitride, and other hard coatings.

Uniform coating thickness: These machines can average deposit coatings on stainless steel panels. Even if it’s big!This ensures consistent performance and appearance.

Energy efficiency: PVD vacuum coaters must less energy than comparable technologies. Because it uses low-pressure plasma technology. compared to other similar technologies.

Automation: The high-performance PVD vacuum coating machine is automatic. This ensures consistent quality and reduces labor costs.

Environmental friendly:PVD vacuum coating is a clean and environmental friendly process. Because it produces no harmful emissions or waste.

03 Main Application

1、Architectural and decorative applications: PVD coating on stainless steel panels enhances the appearance. Making it ideal for architectural and decorative applications. Examples include building facades, interior finishes, and furniture.

2、Automotive and Aerospace industries: PVD coatings can be used in the automotive and aerospace industries. Improve wear and corrosion resistance of stainless steel components. Examples include engine components, brake discs, and turbine blades.

3、Medical equipment: PVD coating can be applied to stainless steel parts in medical equipment. Thus improving its biocompatibility, wear resistance and corrosion resistance.

04 Download

Magnetron sputtering coating

05 Specifications

| Model | ZJ-2624 | ZJ-2830 | ZJ-3118 | ZJ-3131 | ZJ-3531 | ZJ-3731 | |

| Chamber Size(mm) | Ф2600xH2400mm | Ф2800xH3000mm | Ф3100×H1800mm | Ф3100×H3100mm | Ф3500×H3100mm | Ф3700×H3100mm | |

| Application | Hardware industry, decoration industry, ceramics, household appliances industry | LOGO scutcheon, stainless steel show frame, stainless steel parts and sheet, etc. | |||||

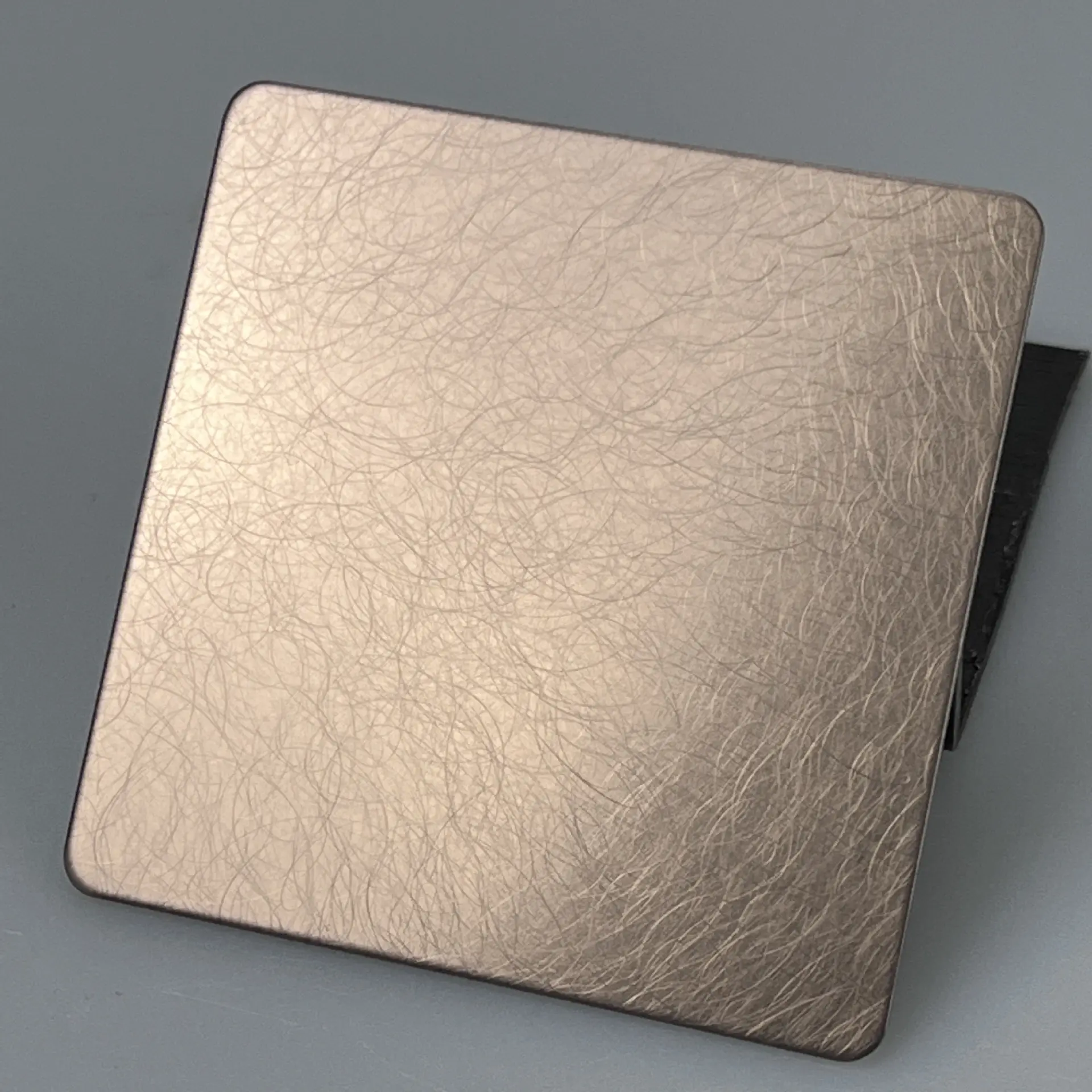

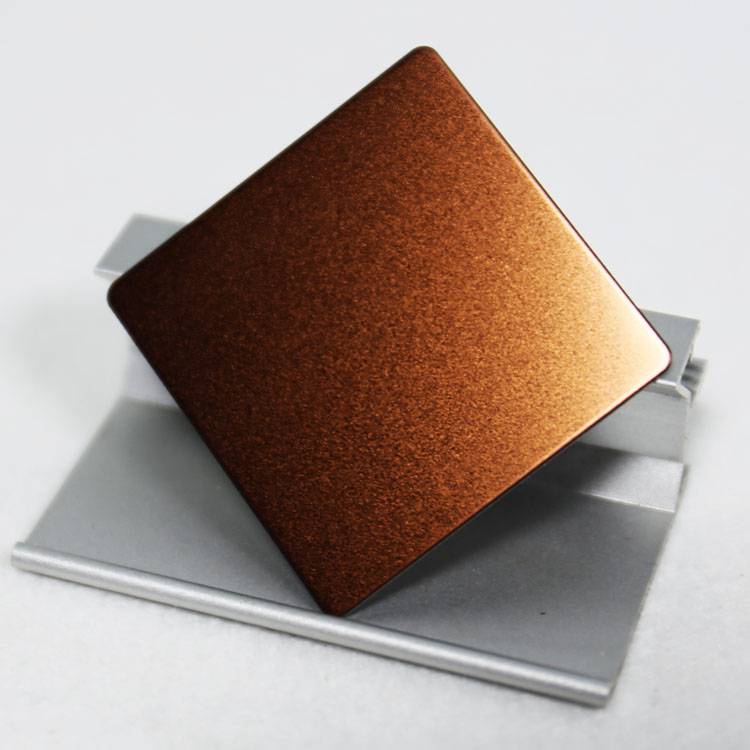

| Coating Film Type | Rose gold | Champagne gold | Japanese gold | Silver | Colorful | Sapphire orchid | Rose red, black and so on |

| Vacuum Chamber | , equip with pumping system and water cooling system | Vertical door, hanging or horizontal cart structure | |||||

| Vacuum System | Sustaining Pump + Mechanical Pump + Roots Pump + Diffusion Pump | Molecule Pump(specific model according to customers' requirements) | |||||

| Vacuum | 1 set diaphragm gauge | 1 set cold cathode | 1 set pirani | ||||

| Supply Type | DC power | MF power | power(bias power,arc power) | ||||

| Ultimate Pressure | 1.0-6.0x10-4Pa | Non-loading cooling | |||||

| Arc Source | 22-28 set | 22-28 set | 26-32 set | 26-32 set | 32-48 set | 32-48 set | |

| Arc Source | 200A-300A | 200A-300A | 200A-300A | 200A-300A | 200A-300A | 200A-300A | |

| Bias Power | 60KW/1 set | 60KW/1 set | 70KW/1 set | 70KW/1 set | 80KW/1 set | 100KW/1 set | |

| Rotation | Multi-axis planetary with frequency control(can be controlled and adjusted) | ||||||

| Baking | Normal temperature ~300C, can be controlled and adjusted(PID temperature control) | ||||||

| Gas | 3 or 4 ways working gas flow control and display system matched with auto gas adding system | Ar, N2, C2H2, O2 | |||||

| Cooling Method | Water cooling circulation | equip with industrial cooling tower | industrial water chiller(refrigerating machine) | cryogenic system(customers provide) | |||

| Controlling | Manual ,half-auto | touch screen operation | PLC or computer controlled | ||||

| Supply Index | Air Pressure0.5-0.8MPa | Water Temperatures25C | Water Pressure20.2MPa | ||||

| Warning | Alarming system will work when hydropenia, over-voltage, circuit break such abnormal situation happensand carry out related protect solution and electric interlock. | ||||||

| Total Power | 165~185KW | 185~200KW | 200~225KW | 225~245KW | 245~265KW | 265~300KW | |

| Output Frequency | Voltage 380V,Frequency 50Hz(equip as customers' national electricity standard) | ||||||

| Occupation Space | 25~55㎡ | 35~55㎡ | 35~55㎡ | 45~55㎡ | 45~55㎡ | 55~75㎡ | |

| Remark | Design and produce special machine according to customers' require, can add magnetron sputtering target,MF twins target,etc. | ||||||