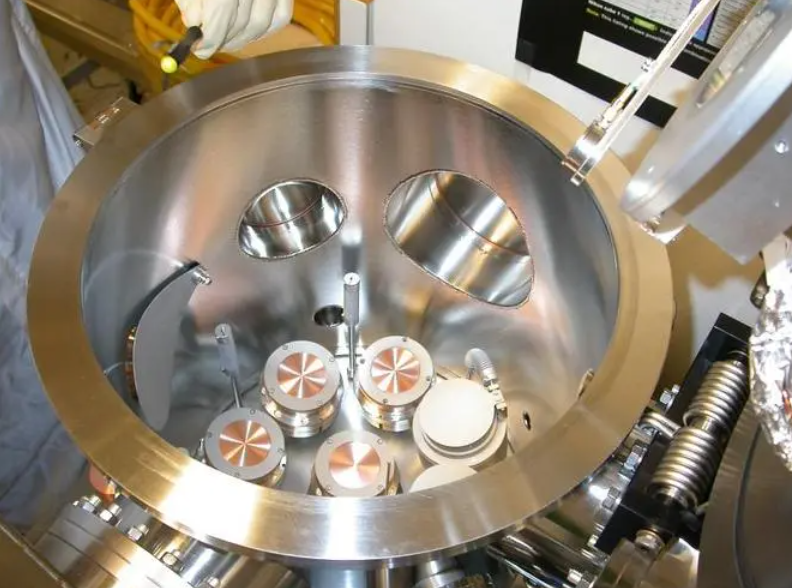

Best Coating Technology: Magnetron Sputtering Vacuum Coating Machine

As the magnetron sputtering vacuum coating technology continues to thrive, Foxin Vacuum Technology Company emerges as a trailblazer in the field. Through their relentless pursuit of innovation, Foxin has expanded the boundaries of what is achievable with thin film coatings. By embracing new materials, improving precision coating techniques, and collaborating with industry partners, Foxin’s machines contribute to technological advancements across diverse sectors.

Modern manufacturing has made a lot of advancements in coating technologies that have improved the durability, performance, and aesthetics of products. Among these breakthroughs is the Magnetron Sputtering Vacuum Coating Machine from Foxin Vacuum Technology Company. It has found applications in a diverse range of industries and revolutionized how materials are coated. In this blog post, we will explore the real-world applications of this technology and the contributions made by Foxin Vacuum Technology Company.

1. Coating for High-Performance Electronics: Magnetron Sputtering Empowering Electronic Devices

In the electronics industry, the demand for high-performance, reliable components is incessant. Magnetron sputtering vacuum coating machines play a pivotal role in producing thin films of materials such as silicon, titanium, and tantalum on electronic substrates. These thin films improve the conductivity, wear resistance, and corrosion resistance of components like semiconductor devices, microchips, and sensors. Foxin Vacuum Technology Company’s precision-engineered machines have enabled manufacturers to enhance the performance of their electronic products while maintaining cost efficiency.

2. Green Energy Innovations: Coatings That Drive Sustainable Technologies

With the world’s growing emphasis on renewable energy sources, magnetron sputtering vacuum coating machines have become an indispensable tool in the production of solar cells and energy-efficient glass coatings. By depositing thin films of materials like indium tin oxide (ITO) and cadmium telluride (CdTe) on solar panels, these machines boost their light absorption capabilities and overall efficiency. Foxin Vacuum Technology Company’s machines have contributed significantly to the solar industry’s expansion, promoting a greener and more sustainable future.

3. The Automotive Industry’s Shield: Enhanced Protection through Advanced Coatings

The automotive sector constantly strives for improved safety and longevity of its vehicles. Magnetron sputtering vacuum coating machines have proven invaluable in creating protective coatings for automotive glass and various metal components. With Foxin Vacuum Technology Company’s cutting-edge solutions, manufacturers can produce scratch-resistant, UV-reflective, and self-cleaning coatings that enhance driver visibility, reduce interior heating, and increase overall vehicle lifespan.

4. Elevating Aesthetics in Architecture: Transforming Buildings with Coated Glass

Architects and designers are increasingly exploring innovative ways to incorporate coated glass in building facades. Magnetron sputtering vacuum coating machines allow for the deposition of vibrant and reflective coatings on glass surfaces, enabling energy-efficient windows and visually striking designs. Foxin Vacuum Technology Company’s machines have been a driving force behind the architectural industry’s transformation, giving rise to the construction of sustainable and visually appealing structures.

5. Cutting-Edge Medical Devices: Pioneering Coatings for Healthcare Innovations

The medical field is continuously evolving, demanding medical devices with enhanced biocompatibility and wear resistance. Magnetron sputtering vacuum coating machines have become instrumental in creating coatings for surgical instruments, orthopedic implants, and dental tools. Through precise control of coating thickness and composition, Foxin Vacuum Technology Company has empowered medical equipment manufacturers to develop safer, more reliable devices, ultimately benefiting patient outcomes.

New Innovations and Trends: Magnetron Sputtering Vacuum Coating Machine

1. The Rise of Magnetron Sputtering Vacuum Coating:

Magnetron sputtering technology has revolutionized the process of depositing thin films onto a wide range of substrates. It provides numerous advantages over conventional coating methods, such as high efficiency, uniform film thickness distribution, and superior adhesion properties. Foxin Vacuum Technology Company recognized the potential of this technique early on and has since been a prominent force in promoting its use across various industries, including electronics, aerospace, automotive, and optics.

2. Advancements in New Materials:

One of the most exciting aspects of Foxin’s magnetron sputtering vacuum coating machine is its ability to work with an extensive array of materials. Traditional sputtering methods were limited to a few materials, but Foxin’s machine has opened the doors to new possibilities. From conventional metals like gold and silver to advanced compounds like nitrides, oxides, and diamond-like carbon (DLC) coatings, the versatility of Foxin’s machine empowers industries to explore innovative applications and products.

3. Enhanced Techniques for Precision Coating:

Precision coating has become a fundamental requirement for many high-tech industries, demanding exceptional control over film thickness and composition. Foxin’s magnetron sputtering vacuum coating machine has taken this challenge head-on by incorporating advanced techniques such as reactive sputtering, ion-assisted deposition, and multi-layer coating processes. These developments have led to the creation of highly customizable coatings that exhibit superior mechanical, optical, and electrical properties.

4. Industry Developments and Collaborations:

In an ever-evolving landscape, Foxin Vacuum Technology Company has remained proactive in fostering collaborations with research institutions and industries alike. By working hand-in-hand with experts and key players, they stay ahead of the curve in understanding market demands and technological challenges. Through these collaborations, Foxin has continuously improved its magnetron sputtering vacuum coating machines, ensuring they meet the specific requirements of diverse applications.

5. Focus on Sustainability and Efficiency:

As global awareness of environmental issues grows, industries are increasingly seeking eco-friendly solutions. Foxin Vacuum Technology Company addresses this concern by investing in energy-efficient designs and sustainable manufacturing processes. By optimizing power consumption and minimizing waste, Foxin’s magnetron sputtering vacuum coating machine contributes to a greener future while maintaining high-performance standards.

6. Integration of Smart Automation:

Automation and digitalization have become vital components of modern manufacturing. In line with this trend, Foxin has integrated smart automation features into their magnetron sputtering vacuum coating machines. Advanced process control systems, real-time monitoring, and data analytics enhance efficiency, reduce downtime, and ensure consistent high-quality coatings.

Conclusion: A World Transformed by Magnetron Sputtering Vacuum Coating Machines

As we have explored the diverse applications of magnetron sputtering vacuum coating machines, it becomes evident that this technology is a catalyst for innovation in numerous industries. From boosting the efficiency of electronic devices to driving the adoption of renewable energy solutions, these machines have undoubtedly revolutionized the coating landscape. Foxin Vacuum Technology Company’s unwavering commitment to excellence has played a pivotal role in empowering manufacturers worldwide with cutting-edge coating solutions. As research and development continue, we can expect even more exciting applications of this remarkable technology in the future, shaping industries and enhancing everyday products in ways we could never have imagined.