News

12 Year Pvd Coating Machine In Foxin

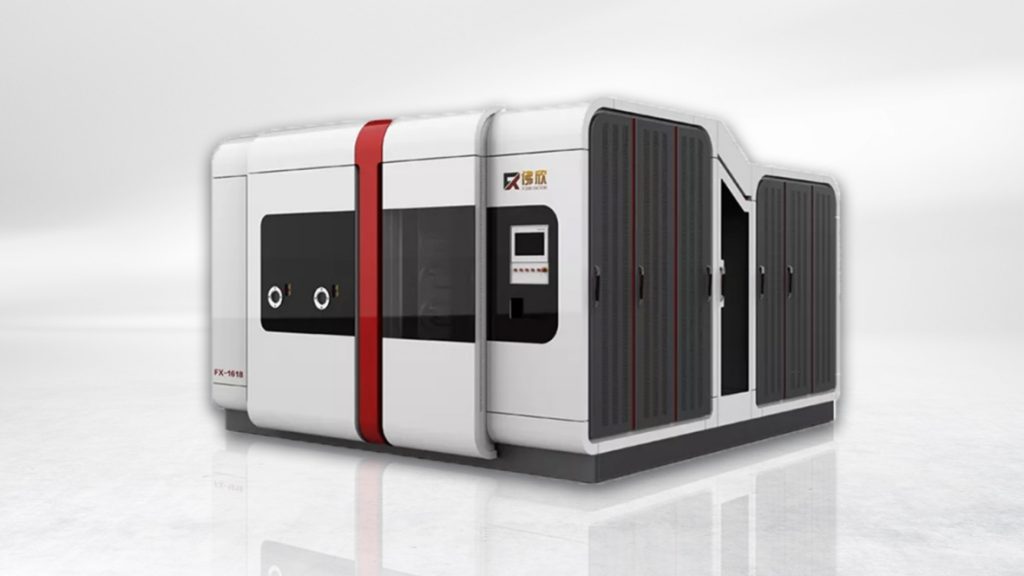

Wholesale Personalized Metal Coating Machine: Foxin Vacuum Technology Company

Metal coating machines have revolutionized various industries by providing durable and visually appealing coatings to metal surfaces. As the demand for customized metal coatings continues to rise, it is crucial to partner with a reliable manufacturer that can deliver high-quality, personalized solutions. This blog will delve into the advantages of wholesale metal coating machines and highlight the reasons why Foxin Vacuum Technology Company stands out as the preferred choice for such equipment.

I. The Need for Personalized Metal Coating Machines:

1.1 Automotive Industry:

The automotive industry heavily relies on metal coating machines to enhance the durability and aesthetics of automobile parts. From exterior components to engine parts, the application of protective coatings not only adds an attractive finish but also protects against corrosion, wear, and environmental factors. Wholesale metal coating machines enable automotive manufacturers to efficiently apply personalized coatings, meeting the unique specifications of each vehicle model.

1.2 Aerospace and Aviation:

In the aerospace and aviation sectors, metal coatings play a critical role in ensuring the safety and performance of aircraft components. Coatings applied through specialized metal coating machines provide protection against extreme temperatures, corrosion, and erosion caused by high altitudes and various environmental factors. By utilizing wholesale metal coating machines, manufacturers in this industry can streamline their production processes and meet the stringent requirements of aerospace regulations.

1.3 Electronics and Consumer Goods:

The electronics and consumer goods industries benefit greatly from metal coating machines for both functional and decorative purposes. These machines allow the application of thin conductive coatings for electronic components, such as circuit boards, enhancing conductivity and shielding against electromagnetic interference. Additionally, metal coatings can provide an elegant and premium finish to consumer goods, including jewelry, watches, and decorative items. Wholesale metal coating machines enable manufacturers to cater to diverse customer preferences efficiently.

II. Foxin Vacuum Technology Company: The Superior Choice for Wholesale Metal Coating Machines

2.1 Cutting-Edge Technology:

Foxin Vacuum Technology Company is a renowned manufacturer at the forefront of metal coating machine innovation. Their commitment to research and development has led to the creation of advanced machines equipped with state-of-the-art features. From precise coating thickness control to efficient material utilization, Foxin’s machines ensure optimal coating results and increased productivity.

2.2 Customization Options:

Recognizing the diverse needs of different industries, Foxin offers wholesale metal coating machines that can be personalized to meet specific requirements. Whether it’s adapting the machine’s dimensions, configuring coating parameters, or integrating automation features, Foxin’s team of experts collaborates closely with clients to deliver tailored solutions.

2.3 Uncompromising Quality:

Quality is a top priority for Foxin Vacuum Technology Company. Their metal coating machines undergo rigorous testing to ensure reliability, durability, and consistent performance. By using premium materials and adhering to strict manufacturing standards, Foxin guarantees machines that deliver exceptional coating results, ultimately leading to customer satisfaction and long-term value.

2.4 Comprehensive Support:

Foxin goes beyond the sale of wholesale metal coating machines by offering comprehensive after-sales support. Their team provides technical assistance, maintenance services, and spare parts to ensure uninterrupted operation and maximize the lifespan of the machines. This commitment to customer support solidifies Foxin’s reputation as a trustworthy and reliable partner.

Ⅲ. Unveiling the Marvels of Metal Coating Machines: Revolutionizing Surface Finishing

3.1 Enhancing Durability and Corrosion Resistance

Under the protective umbrella of metal coatings, metal objects gain exceptional durability and enhanced resistance against corrosion. Metal coating machines utilize sophisticated deposition techniques, such as physical vapor deposition (PVD) and chemical vapor deposition (CVD), to apply a layer of metallic material onto the substrate surface. This process forms a robust barrier that shields the metal from environmental factors, including moisture, chemicals, and oxidation. Industries such as automotive, aerospace, and electronics extensively utilize metal coating machines to enhance the lifespan and performance of their products.

3.2 Elevating Aesthetics and Visual Appeal

Metal coating machines also play a vital role in transforming the appearance and visual appeal of various metal objects. Through techniques like sputtering and evaporation, these machines allow manufacturers to deposit thin, uniform layers of metals like gold, silver, chrome, and titanium onto the surface. This opens up a world of possibilities for creating stunning decorative finishes, such as mirror-like reflections, metallic sheens, and vibrant colors. Industries like jewelry, luxury goods, and architectural design harness the capabilities of metal coating machines to add a touch of elegance and sophistication to their products.

3.3 Improving Conductivity and Functionality

Apart from enhancing durability and aesthetics, metal coating machines offer the ability to improve the functionality of metal objects by altering their surface properties. For instance, by applying thin coatings of conductive metals like copper or silver, manufacturers can transform non-conductive materials into electrically conductive ones. This capability finds application in the production of electronic components, printed circuit boards, and sensors. Additionally, metal coatings can be tailored to provide specific properties such as high reflectivity, low friction, or biocompatibility, enabling advancements in optics, engineering, and medical fields.

3.4 Varied Applications and Industries

The versatility of metal coating machines enables their utilization across a diverse range of industries. In the automotive sector, these machines are employed for coating vehicle components to enhance their resistance to wear, reduce friction, and improve fuel efficiency. In the medical field, metal coating machines are instrumental in developing medical implants that promote better biocompatibility and reduced rejection rates. Similarly, the aerospace industry employs these machines for coating aircraft components to withstand extreme temperatures, enhance fuel economy, and protect against corrosion.

Conclusion:

In today’s competitive market, industries across the spectrum require personalized metal coating machines to meet their unique needs. Wholesale purchasing allows businesses to optimize costs while benefiting from the advantages offered by Foxin Vacuum Technology Company. From automotive manufacturers seeking impeccable coatings to aerospace companies requiring compliance with stringent regulations, Foxin’s cutting-edge technology, customization options, uncompromising quality, and comprehensive support make them the superior choice for metal coating machines. By partnering with Foxin, businesses can elevate their products, improve efficiency, and achieve a distinct competitive edge.