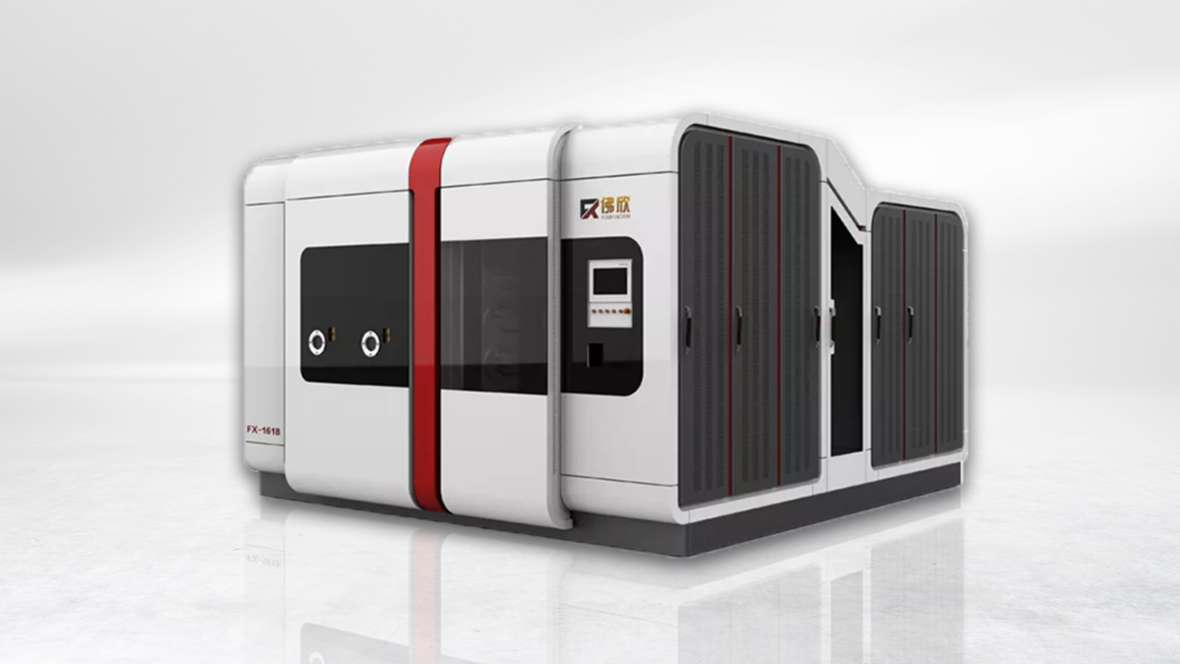

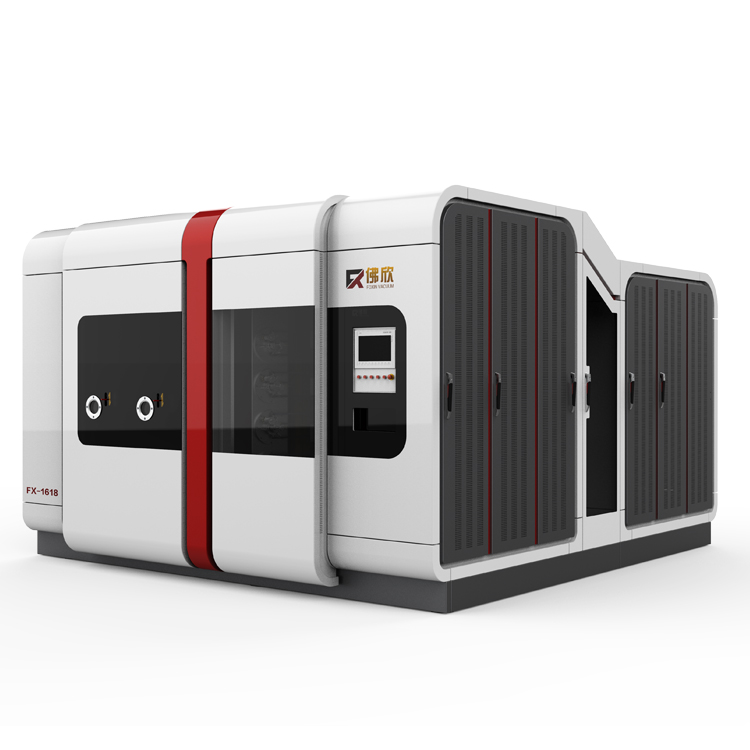

Jewelry metal chain ion PVD electroplating machine

Environmental

Customization

High quality

Delivery time

-

01 Overview

-

02 Benefit

-

03 Working Principle:

-

04 Download

-

05 Specifications

01 Overview

PVD Vacuum Coating Equipment can perform thin-film coating on the surface of spectacle frames. The PVD (Physical Vapor Deposition) process involves a solid material (called a target). The target is vaporize in a vacuum environment. It is then deposited onto the surface of the eyeglass frame. Forms a thin, uniform coating on the surface of spectacle frames. The target material can be selecte according to the desired properties of the coating. Examples include the colour, hardness, adhesion or corrosion resistance of the coating.

02 Benefit

Aesthetic enhancements: PVD coating can be use to create a range of colors and finishes. Including gold, silver, black, and rainbow colors, on glasses frames. This makes your frame more unique and attractive.

Scratch resistance: PVD coating can improve the scratch resistance of eyeglass frames. This can help them last longer. Their appearance is maintaine over time.

Corrosion resistance: PVD coatings can also improve the corrosion resistance of eyeglass frames. This is important in wet or corrosive environments. Examples include proximity to the ocean or industrial environments.

Medical applications: PVD coatings can be use to create biocompatible coatings on eyeglass frames. Suitable for medical applications such as surgical instruments or prosthetic devices.

Industrial applications: It also enhances the performance of the glass frame. such as in protective eyewear for workers in hazardous environments.

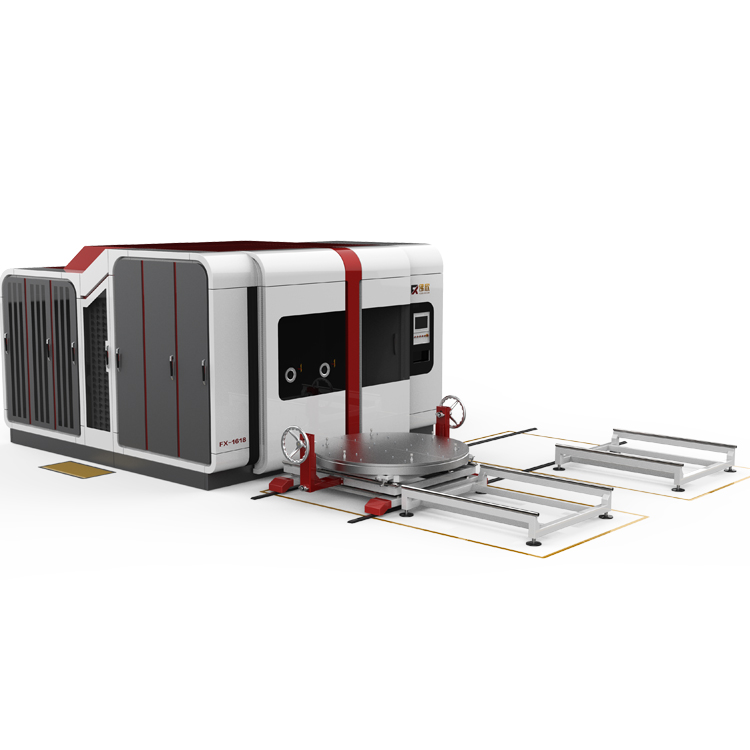

03 Working Principle:

PVD vacuum coating equipment includes:

1、Vacuum chambers, targets, high energy sources. and substrate support. High energy sources such as electron beams or plasmas, for example. Spectacle frames are loade onto substrate supports. Then place in a vacuum chamber. The target material is heate and melted in a vacuum chamber. The resulting ionized particles are deposite on the surface of the glass frame。

2、This device is suitable for a wide variety of coatings. Such as metal, ceramic, diamond-like carbon (DLC) coating. Enhances the durability, scratch resistance and aesthetics of eyeglass frames. The process is also environmentally friendly. As it does not use hazardous chemicals or produce harmful emissions.

04 Download

Vacuum coating overview

05 Specifications

| Model(FOXIN) | FOXIN-PVD-0708 | FOXIN-PVD-0809 | FOXIN-PVD-0910 | FOXIN-PVD-1012 | FOXIN-PVD-1212 | FOXIN-PVD-1215 |

| Vacuum Chamber Size(mm) | Ф700×H800mm | Ф800×H900mm | Ф900×H1000mm | Ф1000×H1200mm | Ф1200×H1200mm | Ф1200×H1500mm |

| Industry | Watch industry, 3C industry, hardware industry, precision mold industry, tool industry, etc | |||||

| Product | Case watchband, drill, hard alloy, milling cutter, punching rod standard parts die, forming die, etc | |||||

| Coating Film Type | Titanium nitride , Titanium nitride carbide, Zirconium nitride , Chromium nitride , Titanium aluminum nitride ,Titanium carbide | |||||

| Vacuum System | The vertical front door structure is equipped with air pumping system and water cooling system | |||||

| Vacuum Measurement | Maintenance pump + mechanical pump + Roots pump + diffusion pump or molecular pump (specific models can be configured according to customer requirements) | |||||

| Vacuum measuring system | One Pilani (MKS) One cold cathode (MKS) One thin film gauge (MKS) | |||||

| Supply Type | Dc power supply, intermediate frequency power supply, pulse power supply (bias power supply, arc power supply) | |||||

| Ultimate Pressure | No-load cold state 1.0-6.0 ×10-4Pa | |||||

| Arc Source | 6set-8set | 6set-8set | 8set-12set | 8set-12set | 10set-14set | 10set-14set |

| Arc Source | 200A-300A | 200A-300A | 200A-300A | 200A-300A | 200A-300A | 200A-300A |

| Bias Power Supply | 20KW/1set | 20KW/1set | 20KW/1set | 30KW/1set | 30KW/1set | 30KW/1set |

| Magnetron power Supply | 1set-2set | 1set-2set | 2set-3set | 2set-3set | 2set-3set | 2set-3set |

| Rotation | Multi-axis planetary male rotation, frequency control (controllable and adjustable) | |||||

| Baking Temperature | Controllable and adjustable from -300℃ to 450℃ to 600℃ (PID temperature control) | |||||

| Gas | The flow control and display system of 3-channel or 4-channel process gas is equipped with automatic gas filling system | |||||

| Gas | Argon, nitrogen, oxygen, acetylene, etc | |||||

| Cooling Method | Water cooling cycle, with industrial cooling tower or industrial chiller (chiller) or cryogenic system. (Provided by customer) | |||||

| Mode of control | PLC+ touch screen operation or computer control, manual, semi-automatic, automatic mode, | |||||

| Supply Index | Air pressure 0.5-0.8MPa, water temperature ≤25℃, water pressure ≥0.2MPa, | |||||

| Warning | Alarm the abnormal situation such as water shortage, overvoltage and undervoltage, circuit break, etc. of pump and target, and implement corresponding protection measures and electrical interlocking function. | |||||

| Total Power | 25~65KW | 45~85KW | 65~105KW | 85~115KW | 95~125KW | 100~130KW |

| Output Frequency | Voltage 380V±5%, frequency 50Hz (according to the customer's national electricity standard configuration) | |||||

| Occupation Space | 15~50m² | 15~50m² | 25~55m² | 25~55m² | 35~55m² | 35~55m² |

| Remark | Non-standard equipment can be designed and manufactured according to user requirements, and magnetron sputtering target and intermediate frequency twin pair target can be installed. | |||||