Improve Brilliance of Surfaces: Overview of PVD Coating

When it comes to enhancing the performance and aesthetics of various products, from your favorite watch to cutting-edge aerospace components, a technology that often plays a silent but crucial role is Physical Vapor Deposition (PVD) coating. PVD coating is an advanced surface treatment method that has become increasingly popular due to its ability to impart exceptional properties to a wide range of materials. This blog provides an insightful overview of PVD coating, comparison, applications, challenges, and solutions, and highlights the expertise of Foxin Vacuum Technology Company, a leading manufacturer in this field.

Overview of PVD Coating: Understanding the Basics of PVD Coating

Physical Vapor Deposition, or PVD, is a process used to deposit a thin layer of material onto the surface of an object. This is achieved by evaporating the source material, which could be a metal or a ceramic, and then condensing it onto the substrate, creating a thin film. The deposition takes place in a vacuum environment, ensuring that the deposited layer adheres tightly to the substrate.

PVD coating processes can be broadly classified into three categories:

1. Evaporation: In this method, the source material is heated to the point of vaporization, and the vaporized particles are deposited onto the substrate.

2. Sputtering: This technique involves bombarding the source material with ions or atoms to eject particles, which are then deposited onto the substrate.

3. Ion Plating: Ion plating is a combination of evaporation and sputtering, enhancing the quality of coatings by introducing ions into the process.

Comparison with Other Coating Techniques: Overview of PVD Coating

While PVD coating offers many advantages, it’s essential to compare it to other common coating techniques to understand its strengths and weaknesses.

1. PVD vs. Electroplating

Electroplating is a popular method for applying a metal coating to various substrates. However, PVD has a clear advantage in terms of environmental impact and durability. Electroplated coatings can be prone to corrosion and may not adhere as well to the substrate. In contrast, PVD coatings are highly resistant to wear and corrosion, making them a superior choice for many applications.

2. PVD vs. Powder Coating

Powder coating is an efficient way to apply a durable finish to metal objects. It is popular in industries like automotive and construction. PVD coatings, though, offer superior hardness and a broader range of color options. They also have a thinner profile, which can be advantageous when preserving fine details on a product’s surface.

3. PVD vs. Paint

Paint is a versatile coating, but it is not as durable or wear-resistant as PVD coatings. Paint can chip or fade over time, while PVD coatings maintain their appearance and functionality for longer periods. Additionally, PVD coatings offer a more premium and refined look for products.

Applications of PVD Coating: Overview of PVD Coating

PVD coating offers a plethora of benefits, making it a preferred choice for a wide range of industries. Here are some of the applications:

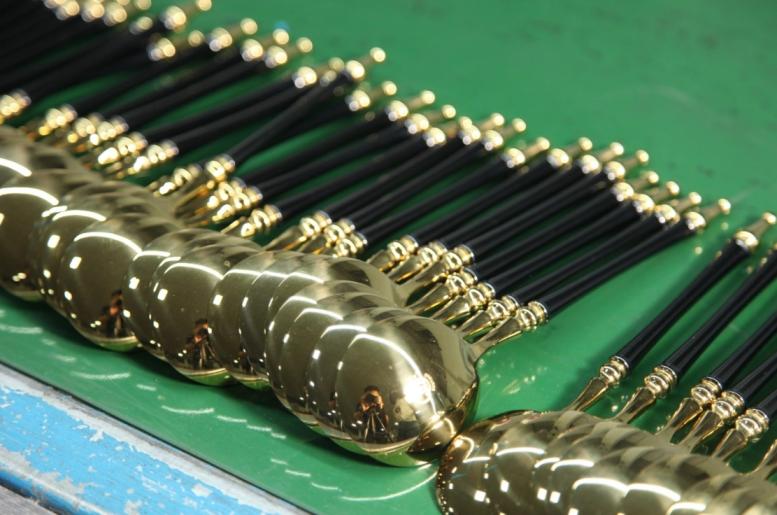

1. Decorative Coatings: PVD coatings are often used in the creation of aesthetically pleasing, durable, and corrosion-resistant finishes on products like jewelry, watches, and architectural hardware.

2. Cutting Tools: PVD-coated cutting tools, such as drill bits and end mills, exhibit improved wear resistance and longer tool life.

3. Aerospace and Automotive: The aerospace and automotive industries rely on PVD coatings to enhance the performance and durability of critical components, including engine parts, pistons, and landing gear.

4. Medical Devices: Surgical instruments and medical implants benefit from PVD coatings as they offer biocompatibility and wear resistance.

5. Optical Coatings: PVD is used to create anti-reflective, anti-scratch, and UV-protective coatings on eyeglasses, camera lenses, and telescopes.

Challenges and Solutions: Overview of PVD Coating

For more understanding overview of PVD coating, let’s dive into the words of various industries. While PVD coating offers numerous benefits, there are challenges involved in implementing the process efficiently and effectively. Foxin Vacuum Technology Company, a leading manufacturer in this field, has developed PVD coating machines to address these challenges:

1. Precise Control

Maintaining control over the PVD coating process is essential for achieving consistent and high-quality results. Foxin’s machines are equipped with advanced controls and monitoring systems that ensure the deposition process is precise and repeatable, meeting the exact requirements of the industry.

2. Adherence to Industry Standards

Different industries have specific standards and regulations to meet. Foxin Vacuum Technology Company’s PVD coating machines are designed with flexibility, enabling customization to adhere to industry-specific standards, whether it be in aerospace, automotive, or any other sector.

3. Efficiency and Cost-Effectiveness

Foxin’s PVD coating machines are not only reliable but also efficient. They offer high deposition rates, making the process cost-effective for industries where time and efficiency are crucial factors.

4. Environmental Considerations

In today’s eco-conscious world, Foxin’s PVD coating machines are designed to be environmentally friendly. They incorporate eco-friendly materials and processes to minimize environmental impact.

Meet Foxin Vacuum Technology Company: Overview of PVD Coating

Foxin Vacuum Technology Company, a prominent name in the PVD coating industry, has been at the forefront of manufacturing high-quality PVD coating equipment for over a decade. They have earned a stellar reputation for their commitment to excellence, cutting-edge technology, and a wide range of solutions.

Their product line includes PVD coating machines for various applications, such as decorative coatings, automotive components, cutting tools, and more. With an emphasis on research and development, they continuously improve and innovate their equipment to meet the ever-evolving needs of industries that rely on PVD technology.

Foxin Vacuum Technology Company’s expert team of engineers and technicians ensures that each system is customized to meet the specific requirements of its clients. They take pride in their ability to deliver turnkey solutions and provide comprehensive technical support, ensuring that their customers achieve the best results with their PVD coating processes.

Conclusion

In conclusion, now you know the overview of PVD coating. PVD coating is a transformative technology that offers numerous advantages to a wide array of industries. It enhances the durability, appearance, and performance of products, making it an invaluable process in today’s manufacturing world. And with companies like Foxin Vacuum Technology leading the way in PVD equipment manufacturing, the future of surface coating looks brighter than ever.