News

12 Year Pvd Coating Machine In Foxin

Transforming Surfaces with Vacuum Metalizing Coating Machine

In today’s ever-evolving world of manufacturing and industrial processes, the demand for high-quality surface coatings has skyrocketed. One technology that has revolutionized the coating industry is vacuum metalizing. This process involves depositing a thin layer of metal onto various substrates to enhance their appearance and functionality. Foxin Vacuum Technology Company, a leading manufacturer in this field, has developed cutting-edge vacuum metalizing coating machines that are empowering industries across the globe.

I. Understanding Vacuum Metalizing Coating Machine:

1.1 The Basics of Vacuum Metalizing:

Vacuum metalizing is a process that utilizes a vacuum chamber to deposit a thin layer of metal, such as aluminum or chrome, onto different materials. This technique is commonly used in industries such as automotive, aerospace, consumer electronics, and packaging. The vacuum metalizing process involves three main steps: surface preparation, metal deposition, and coating finishing. It offers numerous advantages, including improved aesthetics, enhanced durability, and increased resistance to environmental factors.

1.2 Applications of Vacuum Metalizing:

Vacuum metalizing finds applications in a wide range of industries. For example, in the automotive industry, it is used to create reflective surfaces on headlights and interior trims. In the consumer electronics sector, vacuum metalizing is employed to enhance the appearance of smartphone casings, laptop keyboards, and decorative components. Additionally, vacuum metalizing plays a vital role in packaging, providing products with an attractive and eye-catching appearance.

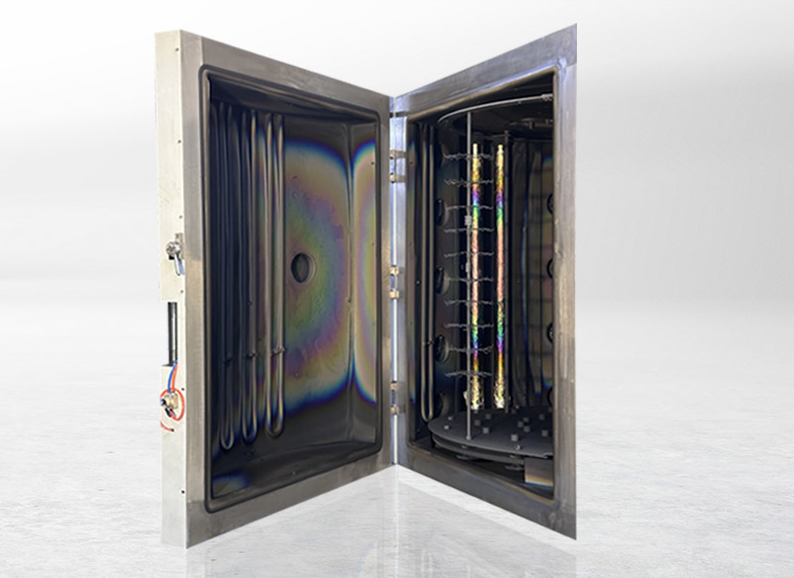

1.3 About Vacuum Metalizing Coating Machine:

A vacuum metalizing coating machine, also known as a vacuum metallizer, is a device used for the process of vacuum metalizing. Vacuum metalizing is a technique used to apply a thin metallic coating onto various materials, such as plastics, glass, ceramics, and metals. The coating provides a decorative, reflective, or protective finish to the object being coated.

II. Foxin Vacuum Technology Company: Revolutionizing Vacuum Metalizing:

2.1 Industry-Leading Vacuum Metalizing Coating Machines:

Foxin Vacuum Technology Company has gained prominence as a top-tier manufacturer of vacuum metalizing coating machines. Their state-of-the-art equipment incorporates cutting-edge technology and engineering expertise to deliver exceptional results. The company offers a wide range of models, each tailored to meet specific industry requirements and applications.

2.2 Vacuum Metalizing Coating Machine Key Features and Benefits:

The vacuum metalizing coating machines by Foxin Vacuum Technology Company boast several key features that set them apart from the competition. These include precise control systems, efficient material utilization, rapid cycle times, and excellent uniformity in coating thickness. Furthermore, the machines are designed to be user-friendly, ensuring ease of operation and maintenance. They offer a high degree of flexibility, allowing for customization and adaptation to diverse coating needs.

2.3 Vacuum Metalizing Coating Machine Process Involves the Following Steps

a) Preparation: The object to be coated is thoroughly cleaned and prepared to ensure proper adhesion of the metallic coating. Any dirt, grease, or contaminants are removed from the surface.

b) Loading: The prepared objects are loaded into the vacuum chamber of the coating machine. The chamber is a sealed environment capable of achieving a high vacuum.

c) Evacuation: The vacuum chamber is evacuated to remove any air or other gases. This is important to create a controlled environment for the coating process and to prevent oxidation of the metal being used for coating.

d) Heating: The chamber is heated to a specific temperature to aid in the evaporation of the metal. The metal used for coating, typically aluminum or other metals like silver, copper, or chrome, is placed in a crucible or source within the chamber.

e) Metal Evaporation: Once the desired temperature is reached, the metal in the crucible begins to evaporate. The evaporated metal atoms form a vapor cloud within the chamber.

f) Deposition: The vaporized metal atoms travel within the vacuum chamber and condense onto the surface of the objects being coated. The metal atoms adhere to the surface and form a thin metallic layer.

g) Cooling and Solidification: After the deposition process, the chamber is cooled, causing the metal vapor to solidify and form a continuous metallic coating on the objects.

h) Unloading: Once the process is complete and the objects have been coated, they are removed from the vacuum chamber.

III. Advancing Technological Innovations:

3.1 Integration of Automation:

Foxin Vacuum Technology Company has embraced automation to streamline the vacuum metalizing process further. Through the incorporation of advanced robotics and intelligent control systems, their coating machines can achieve higher productivity, increased precision, and reduced human intervention. Automation not only enhances efficiency but also minimizes the chances of errors, resulting in consistent and high-quality coatings.

3.2 Sustainable Coating Solutions:

Recognizing the importance of sustainability, Foxin Vacuum Technology Company has made significant strides in developing eco-friendly coating solutions. Their vacuum metalizing machines employ environmentally conscious practices such as efficient material usage, waste reduction, and energy-saving features. By reducing the environmental impact associated with the coating process, Foxin Vacuum Technology Company contributes to a greener future.

3.3 Advanced Process Monitoring and Control:

To further advance its technological innovations, Foxin Vacuum Technology Company has implemented advanced process monitoring and control systems in its vacuum metalizing machines. These systems utilize cutting-edge sensors, data analytics, and real-time feedback mechanisms to optimize the coating process and ensure superior results.

IV. The Future of Vacuum Metalizing:

The vacuum metalizing industry continues to evolve at a rapid pace, driven by advancements in technology and growing market demands. Foxin Vacuum Technology Company remains at the forefront of this transformation, consistently pushing boundaries with its innovative coating machines. As industries seek enhanced surface functionalities and captivating aesthetics, vacuum metalizing will undoubtedly play a pivotal role in meeting these demands.

Conclusion

Foxin Vacuum Technology Company’s vacuum metalizing coating machines have revolutionized the way industries approach surface coatings. With their commitment to technological innovation, sustainable practices, and exceptional quality, they have earned a reputation as a leading manufacturer in the vacuum metalizing industry. As technology continues to advance, the possibilities for vacuum metalizing are limitless. By choosing Foxin Vacuum Technology Company’s cutting-edge machines, manufacturers can unlock the potential of vacuum metalizing to transform their products and stay ahead in today’s competitive market.