News

12 Year Pvd Coating Machine In Foxin

Why Choose Custom PVD Coating for Your Industrial Applications?

In the realm of manufacturing and industrial design, innovations often come in the form of subtle yet transformative technologies. One such innovation making waves across multiple sectors is Custom PVD Coating. This advanced process offers a spectrum of benefits ranging from enhanced durability to unparalleled aesthetics. Among the frontrunners in this domain stands Foxin Vacuum Technology Company, a pioneering force driving the evolution of PVD coating solutions.

The Essence of Custom PVD Coating

1.1 Unveiling the Process

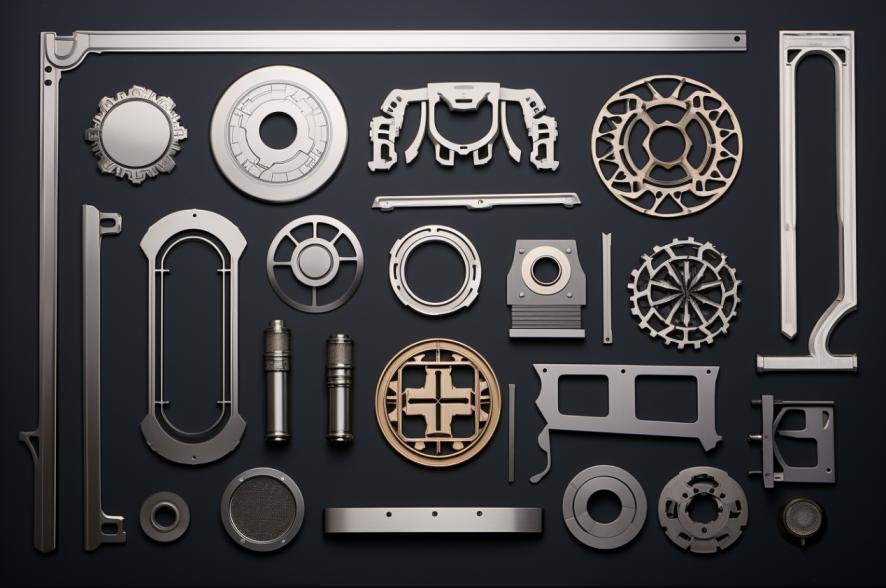

At its core, PVD coating involves the deposition of thin films onto surfaces through a process of physical vaporization and condensation. This technique not only fortifies the substrate’s surface but also bestows it with desirable properties such as wear resistance, corrosion protection, and decorative finishes. Custom PVD coating takes this process a step further by tailoring the coating to the specific requirements of diverse industries.

1.2 Precision Engineering

Customization is the cornerstone of modern manufacturing, and PVD coating exemplifies this principle. By meticulously adjusting deposition parameters like temperature, pressure, and composition, manufacturers can achieve coatings optimized for various applications. This precision engineering ensures that each coated product meets the exacting standards of its intended use, whether it’s a faucet in a luxury hotel or a stainless steel frame in a cutting-edge appliance.

1.3 Versatility in Applications

The versatility of custom PVD coating knows no bounds, permeating industries as diverse as hardware, sanitary appliances, decoration, and household appliances. From faucet fixtures to staircase handrails, from logo signs to stainless steel components, the applications are as varied as the industries they serve. Let’s delve deeper into how custom PVD coating revolutionizes each of these sectors.

Elevating the Hardware Industry

2.1 Enhanced Durability

In the hardware industry, where functionality is paramount, custom PVD coating offers a game-changing advantage: enhanced durability. Tools, fasteners, and machine components subjected to harsh conditions benefit immensely from coatings that resist abrasion, chemicals, and corrosion. Whether it’s extending the lifespan of power tools or safeguarding industrial machinery against wear, custom PVD coatings provide a robust defense against degradation.

2.2 Tailored Solutions for Specialized Needs

Within the hardware industry, specialized applications demand bespoke solutions. Custom PVD coatings cater to these needs by offering tailored formulations optimized for specific substrates and operating environments. Whether it’s aerospace components requiring lightweight coatings or automotive parts necessitating heat-resistant finishes, manufacturers can rely on custom PVD coatings to meet the most demanding specifications.

2.3 Innovating Design Possibilities

Beyond functionality, custom PVD coatings open up new horizons in design innovation. With an extensive palette of colors and finishes at their disposal, designers can imbue hardware products with aesthetic appeal without compromising on performance. From sleek matte black finishes to lustrous metallic hues, the design possibilities are limited only by imagination.

Redefining Sanitary Appliance Standards

3.1 Hygiene and Longevity

In the sanitary appliance industry, where hygiene is paramount, custom PVD coatings offer a hygienic and long-lasting solution. By forming a protective barrier that resists corrosion and prevents bacterial adhesion, these coatings ensure that faucets, showerheads, and bathroom fixtures maintain their pristine appearance while upholding rigorous hygiene standards.

3.2 Anti-Fingerprint Technology

One of the perennial challenges in the sanitary appliance industry is combating unsightly fingerprints and smudges. Custom PVD coatings address this issue head-on with anti-fingerprint technology, which repels oils and residues, leaving surfaces clean and smudge-free. This feature not only enhances the aesthetics of sanitary appliances but also reduces maintenance efforts for end-users.

3.3 Seamless Integration with Design Trends

In an industry where aesthetics play a pivotal role, custom PVD coatings seamlessly integrate with contemporary design trends. Whether it’s the timeless elegance of brushed nickel or the modern allure of rose gold, these coatings elevate the visual appeal of sanitary appliances while offering superior performance and longevity.

Transforming the Decoration Industry

4.1 Artistry Meets Functionality

In the decoration industry, where aesthetics reign supreme, custom PVD coatings serve as a bridge between artistry and functionality. Whether it’s embellishing architectural elements or accentuating interior furnishings, these coatings offer a versatile canvas for designers to unleash their creativity. From intricate patterns to custom logos, the possibilities for decorative embellishments are limitless.

4.2 Environmental Sustainability

Amid growing concerns about environmental sustainability, custom PVD coatings stand out as an eco-friendly solution. Unlike traditional plating methods that rely on hazardous chemicals and generate toxic byproducts, PVD coatings are deposited in a vacuum environment without the use of solvents or heavy metals. This not only minimizes environmental impact but also ensures a safe and sustainable coating process.

4.3 Preserving Heritage with Modern Techniques

In the realm of heritage restoration and conservation, custom PVD coatings play a pivotal role in preserving historical artifacts and architectural landmarks. By applying protective coatings that mimic the appearance of traditional finishes, conservators can safeguard heritage structures against degradation while maintaining their original aesthetic charm. This harmonious blend of modern technology and timeless craftsmanship ensures that cultural treasures endure for generations to come.

Embracing Innovation in Household Appliances

5.1 Seamless Integration with Modern Lifestyles

In the household appliances industry, where convenience and style converge, custom PVD coatings offer a seamless integration with modern lifestyles. From sleek stainless steel refrigerators to minimalist kitchen fixtures, these coatings enhance the visual appeal of household appliances while providing durable protection against everyday wear and tear.

5.2 Personalization and Brand Identity

In an era of personalized products and brand differentiation, custom PVD coatings allow manufacturers to imbue household appliances with distinctive identities. Whether it’s etching company logos onto stainless steel surfaces or customizing finishes to match brand aesthetics, these coatings enable brands to make a lasting impression on consumers while reinforcing brand loyalty.

5.3 Sustainable Solutions for Sustainable Living

As consumers increasingly prioritize sustainability in their purchasing decisions, custom PVD coatings offer a sustainable solution for household appliances. By extending the lifespan of products through enhanced durability and corrosion resistance, these coatings contribute to a circular economy where resources are conserved, and waste is minimized.

Leading the Charge: Foxin Vacuum Technology Company

At the forefront of the custom PVD coating revolution stands Foxin Vacuum Technology Company, a trailblazer in the field of vacuum coating solutions. With a relentless commitment to innovation, quality, and customer satisfaction, Foxin has earned a reputation as a trusted partner for industries seeking to elevate their products through custom PVD coatings.

6.1 Unparalleled Expertise and Technology

With decades of experience and a state-of-the-art facility equipped with advanced coating technologies, Foxin possesses the expertise and resources to deliver bespoke coating solutions tailored to the unique requirements of each industry. Whether it’s optimizing coating parameters for specific substrates or developing proprietary formulations for specialized applications, Foxin’s team of experts is dedicated to exceeding customer expectations.

6.2 Collaborative Partnerships for Success

Foxin understands that successful partnerships are built on collaboration, trust, and mutual respect. That’s why the company works closely with customers throughout the entire coating process, from initial consultation and design to production and quality assurance. By fostering open communication and transparency, Foxin ensures that every coated product meets the highest standards of quality and performance.

6.3 Driving Innovation for a Sustainable Future

As a responsible corporate citizen, Foxin is committed to driving innovation for a sustainable future. Through ongoing research and development efforts, the company seeks to improve coating technologies, optimize resource utilization, and minimize environmental impact. By embracing sustainability as a core value, Foxin aims to lead the industry toward a more sustainable and environmentally conscious future.

6.4 Empowering Industries, Enriching Lives

Foxin’s impact extends far beyond the realm of custom PVD coating. By empowering industries with cutting-edge solutions, the company plays a vital role in enhancing product performance, driving design innovation, and enriching lives. Whether it’s ensuring the reliability of critical hardware components, enhancing the aesthetics of architectural masterpieces, or improving the functionality of household appliances, Foxin’s coatings leave an indelible mark on the world around us.

6.5 Looking Towards the Future

As technology continues to evolve and industries undergo rapid transformations, the role of custom PVD coating in shaping the future becomes increasingly significant. From advancing sustainable manufacturing practices to unlocking new frontiers in design possibilities, the potential applications of custom PVD coatings are virtually limitless. As a trusted partner and innovator, Foxin Vacuum Technology Company remains committed to pushing the boundaries of what’s possible, driving progress, and empowering industries to thrive in an ever-changing world.

Conclusion

In conclusion, custom PVD coating represents a transformative technology that is revolutionizing industries ranging from hardware and sanitary appliances to decoration and household appliances. With its ability to enhance durability, improve aesthetics, and offer sustainable solutions, custom PVD coating is reshaping the way products are designed, manufactured, and experienced. At the forefront of this revolution is Foxin Vacuum Technology Company, a leading provider of custom PVD coating solutions. Through unparalleled expertise, collaborative partnerships, and a commitment to innovation, Foxin is driving positive change and shaping the future of industries around the globe. As we embark on this journey towards a more sustainable and technologically advanced future, the possibilities are boundless, and the potential for impact is immense.