News

12 Year Pvd Coating Machine In Foxin

PVD Steel Finish: What Makes It the Go-To Choice for Surface Coating?

In the realm of hardware, sanitary appliances, decorations, and household appliances, the choice of finishes plays a pivotal role in defining both aesthetics and durability. Among the array of finishes available, PVD (Physical Vapor Deposition) steel finish stands out for its remarkable combination of visual appeal and robustness. In this comprehensive exploration, we delve into the intricacies of PVD steel finish, its applications across diverse industries, and the innovative manufacturing prowess of Foxin Vacuum Technology Company.

Understanding PVD Steel Finish

1.1 Unveiling the Technology Behind PVD

PVD, or Physical Vapor Deposition, is a cutting-edge technology that involves the deposition of thin films onto various surfaces through a process carried out in a vacuum environment. In the case of PVD steel finish, a metallic vapor, typically titanium nitride, is deposited onto stainless steel surfaces using a specialized coating process. This results in a thin, yet incredibly durable layer that enhances the appearance and properties of the steel substrate.

1.2 Key Characteristics of PVD Steel Finish

a. Aesthetic Brilliance: The PVD coating process enables the creation of stunning finishes that range from lustrous golds and bronzes to sleek silvers and blacks. These finishes not only add visual allure but also lend a touch of sophistication to the products they adorn.

b. Exceptional Durability: Unlike traditional coatings, PVD steel finish offers exceptional durability and resistance to wear, corrosion, and tarnishing. This makes it ideal for applications where longevity and performance are paramount, such as in the hardware and household appliances industries.

c. Environmental Friendliness: PVD technology is environmentally friendly as it produces minimal waste and does not involve the use of hazardous chemicals. This aligns with the growing emphasis on sustainability within the manufacturing sector.

Applications Across Industries

2.1 Faucet Finesse: Elevating Bathroom Elegance

a. Pristine Faucet Finishes: PVD steel finish lends an air of luxury to bathroom fixtures, such as faucets and showerheads. Whether it’s a sleek chrome finish or a warm rose gold hue, PVD coatings offer enduring beauty that withstands the rigors of daily use and water exposure.

b. Sanitary Appliance Sophistication: In the sanitary appliance industry, PVD-coated stainless steel components, such as handles and trim, add a touch of elegance to sinks, bathtubs, and toilets. The superior durability of PVD coatings ensures that these components retain their flawless appearance for years to come.

c. Staircase Stunners: Stair handrails and balustrades undergo significant wear and tear due to frequent use and exposure to the elements. PVD steel finish provides a durable and visually appealing solution, enhancing both safety and aesthetics in residential and commercial settings alike.

2.2 Decorative Delights: Elevating Interior Design

a. Distinctive Décor Accents: PVD-coated stainless steel is favored in the decoration industry for its ability to add sophistication and flair to interior spaces. From decorative trim and accents to bespoke furniture pieces, PVD finishes offer limitless design possibilities.

b. LOGO Signs with Lasting Impact: Corporate branding takes on a new dimension with PVD steel finish LOGO signs. The crisp lines and enduring colors of these signs make them a standout feature in corporate offices, retail spaces, and public venues, leaving a lasting impression on visitors and clients alike.

c. Stainless Steel Splendor: PVD coatings enhance the aesthetic appeal of stainless steel frames, trims, and fixtures, making them a popular choice in modern interior design schemes. Whether it’s a residential kitchen or a commercial workspace, the sleek finish and durability of PVD-coated stainless steel add a touch of refinement to any environment.

2.3 Household Appliances: Beauty Meets Functionality

a. Appliance Aesthetics Redefined: From refrigerators and ovens to dishwashers and range hoods, household appliances benefit from the aesthetic and functional advantages of PVD steel finish. The ability to customize colors and finishes ensures seamless integration with diverse kitchen designs.

b. Durable Performance: PVD-coated stainless steel parts and plates exhibit superior resistance to scratches, stains, and fingerprints, making them an ideal choice for high-traffic areas such as kitchen countertops and backsplashes. This durability translates into long-term cost savings for homeowners and manufacturers alike.

c. Eco-Friendly Solutions: As consumers increasingly prioritize eco-friendly products, PVD-coated stainless steel appliances stand out for their sustainability and longevity. By investing in durable, low-maintenance appliances, consumers can reduce their environmental footprint without compromising on style or performance.

Current Market Status of PVD Steel Finish

3.1 Growing Demand Across Industries

PVD steel finish has witnessed a surge in demand across industries such as automotive, aerospace, electronics, sanitary appliances, and household goods. This widespread adoption can be attributed to the superior performance and aesthetic benefits offered by PVD coatings, including enhanced durability, corrosion resistance, and customization options.

3.2 Rising Consumer Expectations

With consumers becoming increasingly discerning about product quality and aesthetics, manufacturers are under pressure to deliver surface finishes that not only meet but exceed expectations. PVD steel finish addresses this need by providing a visually stunning and long-lasting coating solution that enhances the appeal and functionality of a wide range of products.

3.3 Global Expansion of PVD Technology

The global market for PVD coatings is experiencing significant growth, driven by advancements in coating technology, increasing manufacturing capabilities, and expanding application areas. As manufacturers seek to improve product performance and differentiate their offerings in competitive markets, the demand for PVD steel finish is expected to continue its upward trajectory.

Emerging Needs in the PVD Steel Finish Market

4.1 Customization and Design Flexibility

One of the key needs in the PVD steel finish market is the ability to customize coatings to meet specific design requirements and aesthetic preferences. Manufacturers are looking for solutions that offer a wide range of colors, finishes, and surface textures, allowing them to differentiate their products and cater to diverse consumer preferences.

4.2 Enhanced Durability and Performance

In addition to aesthetics, durability, and performance are paramount considerations for manufacturers and consumers alike. PVD steel finish provides a robust coating that withstands wear, abrasion, and corrosion, ensuring that products maintain their appearance and functionality over an extended lifespan. As industries such as automotive and aerospace demand increasingly stringent performance standards, the need for high-quality PVD coatings becomes even more pronounced.

4.3 Sustainability and Environmental Responsibility

With growing awareness of environmental issues and sustainability concerns, there is a growing demand for eco-friendly surface finishing solutions. PVD steel finish offers a more environmentally friendly alternative to traditional coating methods, as it produces minimal waste, eliminates the need for harmful chemicals, and extends the lifespan of products, reducing the overall environmental impact.

Innovative Solutions from Foxin Vacuum Technology Company

5.1 Cutting-Edge Manufacturing Technology

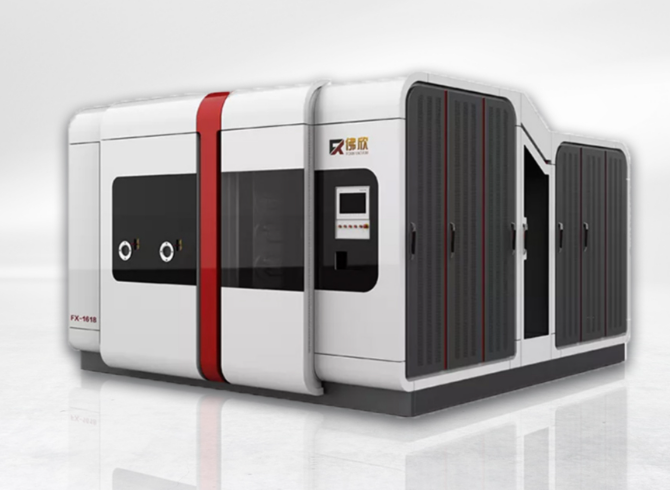

As a leading manufacturer of PVD coating equipment and solutions, Foxin Vacuum Technology Company is at the forefront of innovation in surface finishing technology. With state-of-the-art equipment and expertise in coating processes, Foxin delivers high-quality PVD steel finish solutions that meet the evolving needs of global markets.

5.2 Customization and Design Expertise

Foxin understands the importance of customization and design flexibility in today’s competitive marketplace. With a focus on innovation and collaboration, Foxin works closely with customers to develop tailored PVD coating solutions that meet their specific requirements, whether it’s a unique color, finish, or performance characteristic.

5.3 Sustainability and Environmental Stewardship

Foxin is committed to sustainability and environmental responsibility in its manufacturing processes. By employing eco-friendly technologies and adhering to strict quality control standards, Foxin minimizes environmental impact while delivering superior coating solutions that meet the highest standards of performance and durability.

Conclusion

PVD steel finish represents a perfect marriage of aesthetics and durability, offering a versatile solution for a wide range of applications in the hardware, sanitary appliance, decoration, and household appliances industries. With its exceptional visual appeal, environmental friendliness, and unmatched durability, PVD-coated stainless steel continues to revolutionize surface finishing techniques. As industry leaders like Foxin Vacuum Technology Company continue to innovate and refine PVD coating technology, the future promises even more exciting possibilities for this transformative surface treatment.