News

12 Year Pvd Coating Machine In Foxin

Exploring the Applications and Requirements of Jewelry Coating Machines

In the world of jewelry, the brilliance and longevity of the pieces are of utmost importance. To enhance these qualities, jewelry coating machines have emerged as invaluable tools for the industry. These machines provide a variety of coating applications, ranging from protecting delicate gems to adding a touch of uniqueness to jewelry pieces. In this blog, we will delve into the different applications of jewelry coating machines and outline the requirements for operating them effectively.

Applications of Jewelry Coating Machines:

1. Protective Coatings:

Jewelry coating machines are primarily used to apply protective coatings to jewelry pieces. These coatings act as a shield against environmental factors, preventing tarnishing, scratching, and fading. By employing a jewelry coating machine, manufacturers can extend the lifespan and beauty of their creations, ensuring customer satisfaction and loyalty.

2. Decorative Coatings:

Beyond protection, jewelry coating machines also facilitate the application of decorative coatings. These coatings can add a lustrous sheen, vibrant colors, or unique textures to jewelry pieces, making them visually appealing and captivating. Whether it’s a matte finish or a high-gloss shine, jewelry coating machines offer endless possibilities for enhancing the aesthetic appeal of jewelry.

3. Anti-Allergenic Coatings:

Some individuals are sensitive to certain metals commonly used in jewelry. To cater to such customers, jewelry coating machines enable the application of anti-allergenic coatings. These coatings create a barrier between the wearer’s skin and the metal, reducing the risk of irritation or allergic reactions. By providing this option, jewelry manufacturers can expand their customer base and cater to a wider range of preferences.

Requirements for Operating a Jewelry Coating Machine:

1. Technical Expertise:

Operating a jewelry coating machine requires a certain level of technical expertise. Individuals should possess a thorough understanding of the machine’s functionalities, controls, and maintenance requirements. This knowledge ensures smooth operations, optimal performance, and minimal downtime. Training programs or certifications offered by the manufacturer can help operators acquire the necessary skills.

2. Safety Measures:

Jewelry coating machines involve working with chemicals, high temperatures, and potentially hazardous materials. Operators must adhere to strict safety protocols to safeguard themselves and the workplace. This includes wearing appropriate protective gear, following handling instructions for chemicals, and ensuring proper ventilation in the working area. Regular maintenance and inspections of the machine’s safety features are also crucial.

3. Quality Control:

Maintaining consistent quality is paramount in the jewelry industry. Operators of jewelry coating machines should have an eye for detail and possess quality control skills. They should monitor the coating process carefully, ensuring that the thickness, adhesion, and appearance of the coatings meet the desired standards. Conducting regular tests and inspections helps to identify and rectify any issues promptly.

4. Maintenance and Cleaning:

To ensure the longevity and efficiency of a jewelry coating machine, regular maintenance, and cleaning are essential. Operators should follow the manufacturer’s guidelines for routine inspections, cleaning procedures, and replacing worn-out parts. By keeping the machine in optimal condition, operators can maximize its lifespan and minimize the risk of breakdowns or subpar results.

Manufacturer: Foxin Vacuum Technology Company:

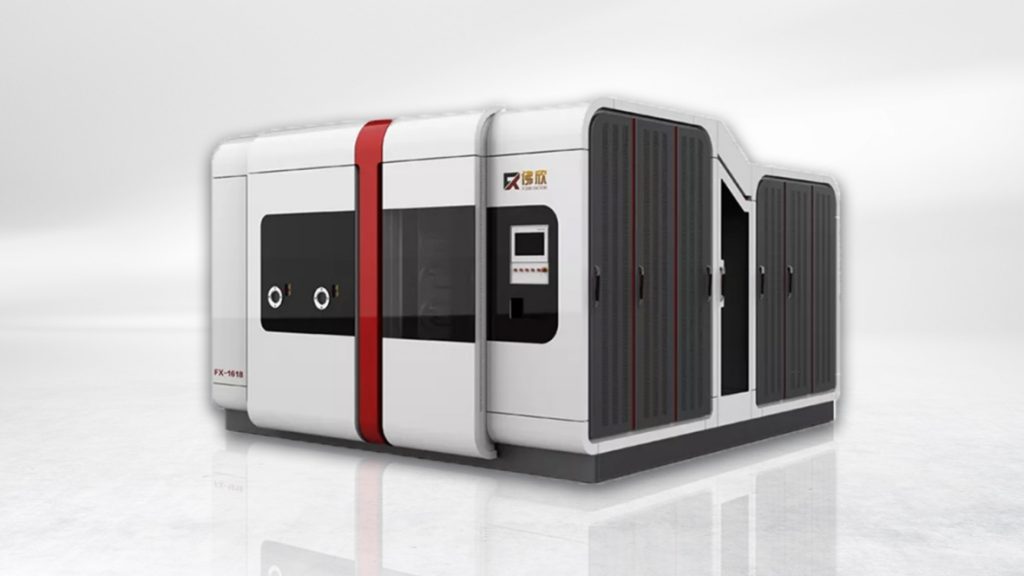

Foxin Vacuum Technology Company is a leading manufacturer in the field of vacuum coating technology, specializing in the production of high-quality jewelry coating machines. With its commitment to innovation and advanced manufacturing processes, Foxin has established itself as a trusted brand in the industry. Their range of jewelry coating machines offers cutting-edge features and superior performance, catering to various industries such as the watch industry, 3C industry, sanitary ware industry, and jewelry industry.

1. Titanium Coating Film for Enhanced Durability

One of the key features of Foxin’s jewelry coating machines is the use of titanium coating film. Titanium coating provides excellent hardness and durability, making it ideal for enhancing the appearance and longevity of jewelry and other products. The coating process ensures a uniform and smooth coating, resulting in a high-quality finish that is resistant to wear and corrosion.

2. Advanced Vacuum System and Measurement

Foxin’s jewelry coating machines are equipped with an advanced vacuum system, including a vertical front door structure, air pumping system, and water cooling system. This combination ensures efficient and reliable vacuum operation during the coating process. The vacuum measurement system comprises components such as a maintenance pump, mechanical pump, Roots pump, diffusion pump, or molecular pump, which can be configured based on customer requirements. Additionally, the machines feature vacuum measuring systems like One Pilani (MKS), One cold cathode (MKS), and One thin film gauge (MKS) for accurate monitoring of the vacuum levels.

3. Power Supply and Arc Source Options

To meet various coating requirements, Foxin’s jewelry coating machines offer different power supply options. These include DC power supply, intermediate frequency power supply, and pulse power supply (bias power supply, arc power supply). The machines are equipped with multiple arc sources ranging from 4 to 18 sets, with power ratings between 200A and 300A. The bias power supply ranges from 20KW to 60KW, providing precise control over the coating process.

4. Comprehensive Control and Monitoring Capabilities

Foxin’s jewelry coating machines come with various control options, including PLC+ touchscreen operation, computer control, manual, semi-automatic, and automatic modes. The user-friendly interface allows for easy operation and parameter adjustment. The machines also feature a comprehensive warning system that alerts users to abnormal situations such as water shortage, overvoltage, undervoltage, and circuit breaks. These protective measures ensure the safety and reliability of the equipment.

5. Highly Versatile Jewelry Coating Machines

Foxin’s jewelry coating machines are designed to meet the diverse needs of different industries. They offer a range of models, including the FOXIN-IP-0710, FOXIN-IP-1012, FOXIN-IP-1212, FOXIN-IP-1412, FOXIN-IP-1612, and FOXIN-IP-1813. Each model comes with its specific chamber size, allowing for different sizes of jewelry and other products to be coated. From smaller items like watch accessories and mobile phone accessories to larger items like clothing, lighting, sanitary ware, hardware bags, glass, ceramics, and plastic, the jewelry coating machines are capable of coating a wide range of materials.

Conclusion:

Jewelry coating machines play a vital role in the jewelry industry, enabling manufacturers to enhance the brilliance, durability, and aesthetic appeal of their creations. From protective coatings to decorative finishes and anti-allergenic options, these machines offer versatile applications that cater to diverse customer preferences. By fulfilling the requirements of technical expertise, safety measures, quality control, and maintenance, operators can harness the full potential of jewelry coating machines, delivering exquisite pieces that captivate and endure.